The Bridgeport Torq-Cut 22 is a smaller CNC vertical machining center. It comes fitted with a grease lubricated and belt driven spindle capable of running up to 7,500 rpm.

Read More

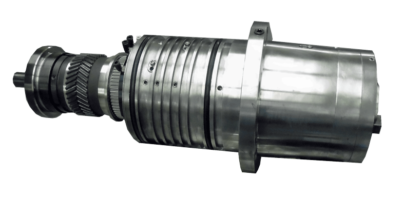

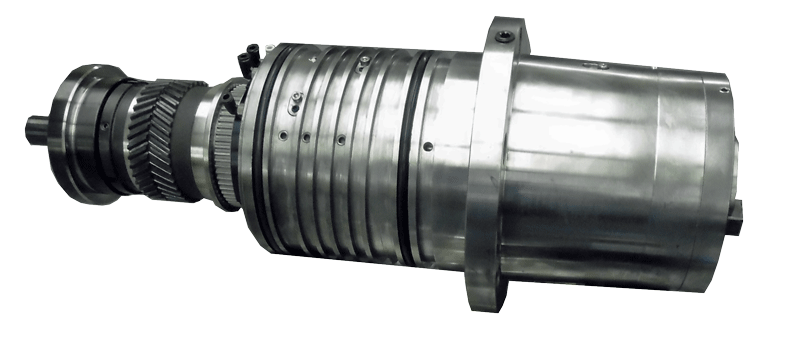

Doosan DMV5025 Spindle Repair

The Doosan DMV5025 is a large vertical machining center capable of high production work. It comes equipped with a pulley driven spindle lubricated by oil mist and capable of running up to 12,000 rpm.

CHALLENGE

This spindle was seized upon receipt. During breakdown, we discovered that the #1 front bearing failed and that debris was obstructing the front housing drain. Dimensional analysis revealed that the tooling taper ID was worn with poor tool contact with 6µ runout.

Our evaluation uncovered the following issues needing to be addressed in repair:

- Drive dogs (keys) showed visible wear

- Gripper fingers (collet) showed significant wear

- Drawbar shaft showed light spring scoring

- Bearing housing bore & outer bearing spacer OD were scored from debris

- Spacer was usable but housing needs attention

- Rotary union drive nut (connecting nut) showed wear on outside diameter and drive ears

SOLUTION

We were able to reuse the drive keys, drawbar, and spacer from the original spindle. The tooling taper ID was kiss ground to address runout and ensure good contact when installed back in service. The bearing housing bore required grind, chrome-plate, and finish grind process.

All parts were thoroughly cleaned prior to being reassembled with new bearings, Bellevilles, grippers, rotary union and drive nut, and hardware.

RESULT

After reassembly of all components, adjusting bearing preload, and undergoing break-in and testing procedures, this spindle passed our final quality inspection before being returned to our customer with a 1-year warranty.

DETAILED CAUSE OF FAILURE

Does your spindle need repair? GET A QUOTE TODAY