The Bridgeport Torq-Cut 22 is a smaller CNC vertical machining center. It comes fitted with a grease lubricated and belt driven spindle capable of running up to 7,500 rpm.

Read More

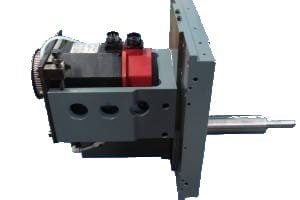

Elb Grinder Spindle Repair

The Elb Grinder spindle is grease lubricated and belt driven. This makes it capable of running up to 5,000 rpm.

CHALLENGE

This Elb Grinder spindle was previously disassembled before arriving at Northland Tool and Electronics. The customer provided used and new front and rear bearings. The used front and rear bearings contained grease which was contaminated with coolant and grinding swarf. We also noted that the front cover and bearing spacers had been damaged. The front bearing spacer was undersized and has a shim. The critical dimensions were then measured and we found some issues to be addressed. First, the 45mm rear bearing journal was worn undersized and tapered. Second, the front and rear shoulders had excessive runout. Third, the front seal journal on the shaft was severely worn, customer indicated that they do not use a seal. Lastly, the 90mm front and 75mm rear housing bores were worn oversized up to 3x ISO, egged, and tapered.

SOLUTION

The following actions were performed on this Elb Grinder spindle:

- Clean, inspect overall dimensions

- Rework front cover and rear bearing spacer

- Manufacture and install a new front bearing spacer (eliminate shim)

- Manufacture and install bearing sleeves in the front and rear housing bores

- Grind, chrome plate, and finish grind the shaft seal journal and rear bearing journal

- Kiss grind both shaft shoulders

- Install NTE-supplied bearings

- Replace o-rings and assembly screws

RESULT

After reassembly of all components, adjusting bearing preload, and undergoing break-in and testing procedures, this spindle passed our final quality inspection before being returned to our customer with a 1-year warranty.

Does your spindle need repair? GET A QUOTE TODAY