The Bridgeport Torq-Cut 22 is a smaller CNC vertical machining center. It comes fitted with a grease lubricated and belt driven spindle capable of running up to 7,500 rpm.

Read More

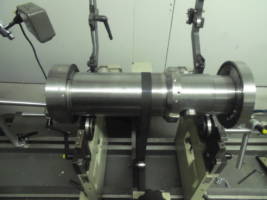

Ingersoll T1000 Spindle Repair

The Ingersoll T1000 spindle is grease lubricated, direct driven, and capable of running up to 6,000 rpm.

CHALLENGE

Our customer supplied a new shaft to be used for this repair. Upon inspection, we found that the rear bearing housing spun inside of the cast housing causing the bearings to fail and housing damage. The rear housing also rubbed out on the drive coupling. We also noted that the bellevilles were worn, but the gripper fingers looked good. Lastly, the coolant nozzles were damaged and the coolant nozzle pressure adjustment valve stem was bent. No other dimensional deviations were noted for the repair.

SOLUTION

The following actions were performed on this Ingersoll T1000 spindle:

- Clean, inspect overall dimensions

- Manufacture a new rear bearing housing

- Manufacture a key

- Machine the drive coupling

- Replace old shaft with customer supplied shaft

- Balance the new shaft on our Schenk Balancer

- Replace bearings, impro seal, bellevilles, coolant nozzles,seals, orings, screws, valve stem and valve stem sleeve

RESULT

After reassembly of all components, adjusting bearing preload, and undergoing break-in and testing procedures, this spindle passed our final quality inspection before being returned to our customer with a 1-year warranty.

DETAILED CAUSE OF FAILURE

Does your spindle need repair? GET A QUOTE TODAY

More Case Studies

Repair History - Here are examples of similar spindle repairs that may contain additional information that will help you. If you have additional questions, please contact us.

It’s a fact of machining — eventually, even top-of-the-line turning machines will experience a spindle failure. Spindles endure tension, torsion, heavy loads, and speeds up to and beyond 150,000 RPM, to name a few of the standard stressors.

Read More