The Bridgeport Torq-Cut 22 is a smaller CNC vertical machining center. It comes fitted with a grease lubricated and belt driven spindle capable of running up to 7,500 rpm.

Read More

Matsuura H.Plus-300 Spindle Repair

The Matsuura H.Plus-300 is a CNC horizontal machining center with a built in pallet changer. It comes equipped with a grease lubricated and coupling driven spindle capable of running up to 15,000 rpm.

CHALLENGE

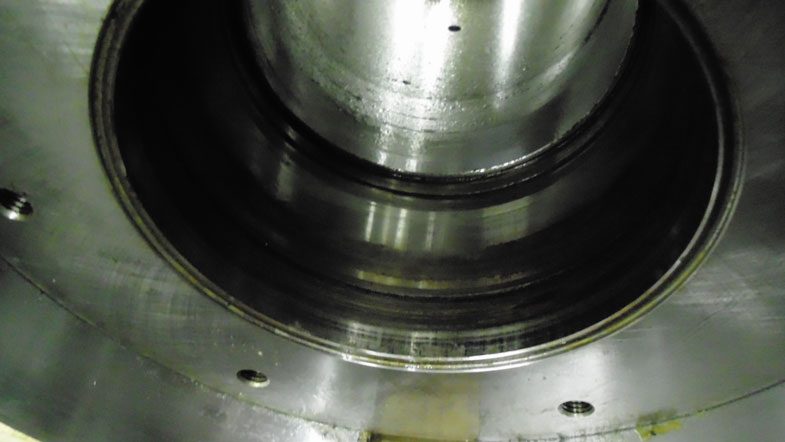

This spindle came to us four years after we initially rebuilt it for our customer. Upon disassembly, we first noticed that the entire interior of the spindle was contaminated with coolant, even in the rear roller bearing. The #1 front angular contact bearing was thoroughly contaminated. We observed heavy fretting on the outer races of both front bearings and in the front housing bore. The housing was egged and oversized by up to 30µ where the bearings are located (ISO is ±7.5µ). We also spotted wear on several other spindle components that ranged from slight to significant. The tooling taper had excessive runout, and the gripper (collet) fingers, gripper sleeve, and drawbar t-bar pusher were worn on critical contact surfaces. The drawbar shaft also had significant wear from the action of the gripper fingers and the drawbar spring, which had left deep chatter marks. Our overall conclusion was that the spindle bearings and the other components were simply fatigued and worn from use.

SOLUTION

We performed a grind, chrome plate, and finish grind of the front housing bore to bring that ID back to spec, which will help to extend the life of the new angular contact bearings. Because our customer does not use dual-contact Big-Plus tooling in this machine, we were able to correct the excessive taper runout with a simple one-step kiss grind. We reassembled the spindle with all new bearings, o-rings & assembly screws, and installed a brand new drawbar, spring & gripper assembly which corrected all of the wear issues we had observed.

RESULT

After reassembly of all components, adjusting bearing preload, and undergoing break-in and testing procedures, this spindle passed our final quality inspection before being returned to our customer with a 1-year warranty.

DETAILED CAUSE OF FAILURE

Does your spindle need repair? GET A QUOTE TODAY

More Case Studies

Repair History - Here are examples of similar spindle repairs that may contain additional information that will help you. If you have additional questions, please contact us.

It’s a fact of machining — eventually, even top-of-the-line turning machines will experience a spindle failure. Spindles endure tension, torsion, heavy loads, and speeds up to and beyond 150,000 RPM, to name a few of the standard stressors.

Read More