The Bridgeport Torq-Cut 22 is a smaller CNC vertical machining center. It comes fitted with a grease lubricated and belt driven spindle capable of running up to 7,500 rpm.

Read More

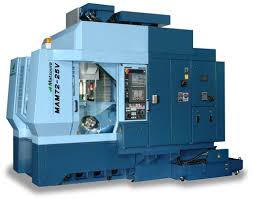

Matsuura MAM72-25V Spindle Repair

The Matsuura MAM72-25V is a CNC vertical machining center designed for 5-axis machining. The main spindle is grease lubricated and coupling driven capable of running up to 15,000 rpm.

CHALLENGE

This Matsuura MAM72-25V spindle came to us from our customer who stated that the spindle had severe vibration. Incoming test showed the drawbar pull force was low and the bearings felt very rough when spun by hand. Upon disassembly we found catastrophic failure of the front bearing, the front housing where the #2 bearing sits was oversized and fretted as well. No other dimesional deviations were noted.

SOLUTION

The following actions were performed on this Matsuura MAM72-25V spindle:

- Clean all parts of the spindle

- Replace all bolts, o-rings, and bellevilles

- Replace bearings with permanent grease bearings

- Grind, chrome plate, and finish grind the housing

RESULT

After reassembly of all components, adjusting bearing preload, and undergoing break-in and testing procedures, this spindle passed our final quality inspection before being returned to our customer with a 1-year warranty.

DETAILED CAUSE OF FAILURE

Does your spindle need repair? GET A QUOTE TODAY

More Case Studies

Repair History - Here are examples of similar spindle repairs that may contain additional information that will help you. If you have additional questions, please contact us.

It’s a fact of machining — eventually, even top-of-the-line turning machines will experience a spindle failure. Spindles endure tension, torsion, heavy loads, and speeds up to and beyond 150,000 RPM, to name a few of the standard stressors.

Read More