The Bridgeport Torq-Cut 22 is a smaller CNC vertical machining center. It comes fitted with a grease lubricated and belt driven spindle capable of running up to 7,500 rpm.

Read More

Mitsui Seiki HT3A Spindle Repair

The Mitsui Seiki HT3A is a CNC horizontal machining center that has a built in pallet changer. It comes standard with an oil mist lubricated and stator driven spindle capable of running up to 12,000 rpm.

CHALLENGE

Our customer contacted us for expedited repair of a Mitsui Seiki HT3A spindle. They indicated that they were experiencing random inconsistencies in the depth of their cuts, varying from +0.001″ to +0.007″ too deep.

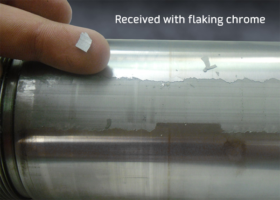

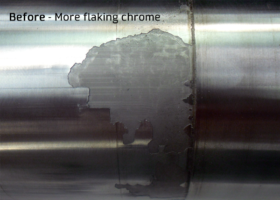

Upon initial intake of this spindle we noted that the front bearing middle ID spacer spun on the shaft. Closer inspection revealed that the spacer was damaged and previously-applied plating was flaking off. Chrome plating was very thin and poorly adhered to the 80mm front bearing journal. During removal of the bearings and spacers, chrome plating was flaking off of the 80mm bearing journal. The CAT #40 tooling taper ID (also previously plated) had excessive run-out measuring 14µm.

SOLUTION

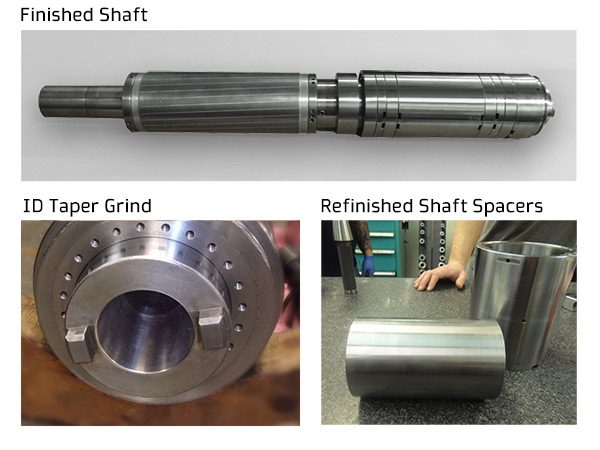

We needed to machine a new replacement front bearing middle ID spacer. Extensive grinding was required to address flaking chrome plating and extensive taper run-out. The shaft required a grind, chrome-plate, and finish grind to the 80mm front bearing journal & the tooling taper ID. After a thorough cleaning, the spindle was rebuilt with all new bearings and and reassembled with a newly fabricated spacer.

When we initially checked with our supplier, they gave us a 4 month lead time for bearings. We were able to source a different vendor for quicker turnaround, and we had this spindle in and out of our facility and back in our customer’s hands in 10 days.

RESULT

After reassembly of all components, adjusting bearing preload, and undergoing break-in and testing procedures, this spindle passed our final quality inspection before being returned to our customer with a 1-year warranty.

DETAILED CAUSE OF FAILURE

Does your spindle need repair? GET A QUOTE TODAY

More Case Studies

Repair History - Here are examples of similar spindle repairs that may contain additional information that will help you. If you have additional questions, please contact us.

It’s a fact of machining — eventually, even top-of-the-line turning machines will experience a spindle failure. Spindles endure tension, torsion, heavy loads, and speeds up to and beyond 150,000 RPM, to name a few of the standard stressors.

Read More