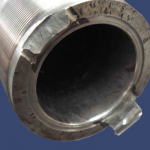

Northland Tool BIG PLUS Spindle Repair Services

Ensure you’re getting the maximum performance from your BIG PLUS tooling by having your spindles repaired by Northland Tool & Electronics.

To receive the maximum benefit from your BIG PLUS tooling your spindle must meet the same high quality standards you have come to expect from BIG PLUS. Northland Tool has worked closely with the engineers at BIG Kaiser to develop a repair program exclusively for your BIG PLUS spindles. Special care and attention will be given to the tooling interface, drawbar, bearing journals and balance, insuring that we provide the extreme accuracy required. The tooling interface will undergo specific quality checks throughout the repair process using only BIG PLUS certified equipment provided to Northland Tool by BIG Daishowa Seiki.

Our in house grinding department has over 20 years experience with the close tolerance work required for spindle parts. Northland Tool works closely with BIG Kaiser to insure the highest quality standards are met with your spindle repair.

Click Here for a Spindle Evaluation by our experienced staff.

- Machine Tool Spindle Bearing Lubrication: What To Know

- Delaying Spindle Service Causes More Damage, Costly Repairs

- What Does It Mean to Be a Factory Authorized Big Plus Spindle Rebuilder?

- Precision Machining in a World of Microns

- GPG: Grind-Plate-Grind Process Explained

- What Is the Spindle Repair Process?