Okuma Howa 438 spindle repair solutions

Our customer acquired several Okuma Howa machines from a sister plant that closed. The installation of the machines was anything but smooth. The first problem they ran into was a spindle that was making noise and leaving chatter marks on the parts. We concluded the bearings were worn and pulled the spindle for repair.

Our breakdown evaluation found the failure of the rear bearing to be the main cause of failure. Contamination had worked its way through the rear cover into the rear bearing causing the grease in the rear roller bearing to fail.

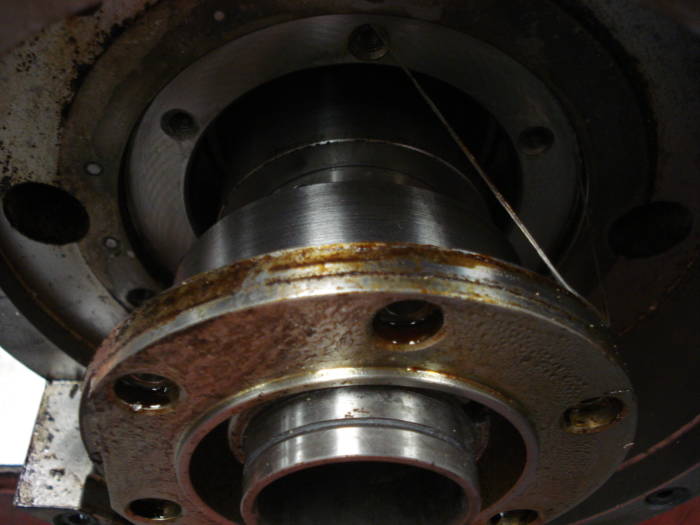

Here is a view of the back cover and the contamination that was present.

Further investigation revealed that the drawbar system for this spindle had been modified and could not function properly.

After we repaired the spindle we sent the technician who assembled the spindle to work with the dealer who was installing the spindle. Because of the modifications done to the spindle at the other facility ajustments needed to be made to the spindle during the instalation process. The installer was happy to have our assitance.

By working with the dealer and our customer we were able to get the machine up and running and solve many of the issues they were having with the imported machines.

CONTACT US TO GET MORE INFORMATION FROM A SPINDLE REPAIR SPECIALIST

- Machine Tool Spindle Bearing Lubrication: What To Know

- Delaying Spindle Service Causes More Damage, Costly Repairs

- What Does It Mean to Be a Factory Authorized Big Plus Spindle Rebuilder?

- Precision Machining in a World of Microns

- GPG: Grind-Plate-Grind Process Explained

- What Is the Spindle Repair Process?