Precision Grinding Services

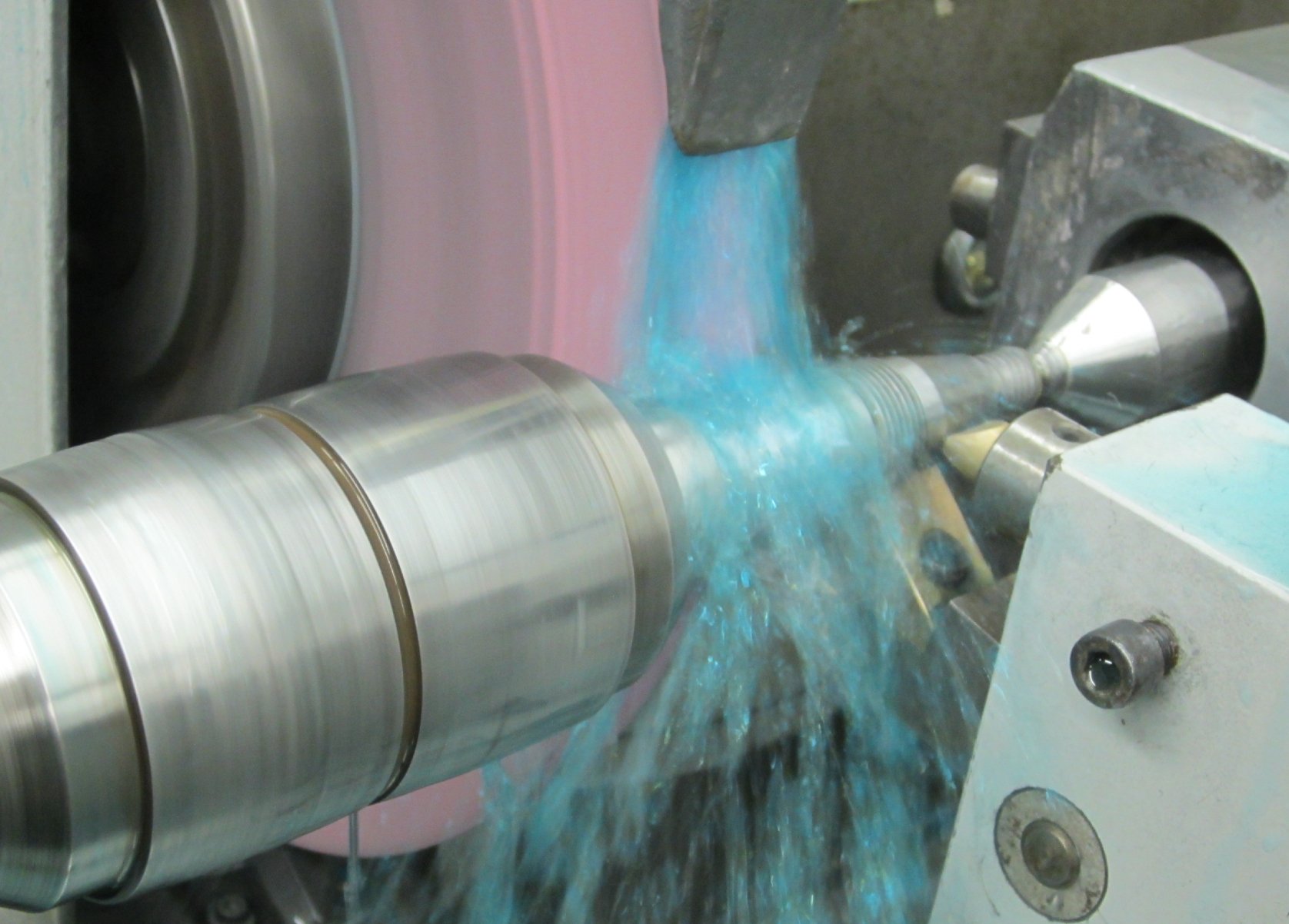

Northland Tool specializes in precision outside diameter (OD) and internal diameter (ID) grinding for your short run grinding job needs.

Whether you have a one-time need for a special project or you have ongoing cylindrical grinding work that you need to outsource, you can learn more about our grinding services below. Or simply request a quote:

Precision cylindrical grinding is used to achieve higher precision tolerances than other machining processes can deliver. Grinding wheels are made of an abrasive material that can alter the shape, size, and surface texture of workpieces made of metal, ceramic, or mineral.

Precision cylindrical grinding is required for pieces used in the following applications and industries:

- Aerospace and scientific instruments

- Electronic components

- Medical devices and smart medical tools

- Automotive

- Printing

- Transportation

- And more!

At Northland Tool, we have the ability to grind parts to within a 0.0001” tolerance. This pertains to both large pieces used in the oil and gas industry and to smaller pieces used in surgical equipment.

Our grinding department includes four Kellenberger 1000U cylindrical grinding stations, giving us state-of-the-art-precision to hold extremely tight tolerances.

We also have the following in our shop:

- GMN Cup Wheel Grinding Machine

- 2 surface grinders

- Several complete sets of BIG-PLUS® gaging solutions

- Large selection of Stotz air gaging solutions for spindle taper quality control

- Extensive spindle-specific metrology department

We adhere to industry-specific standards as detailed in ISO 9001

When you choose Northland Tool, you leverage over 40 years of precision grinding experience. Our ability to hold tight tolerances guarantees that we can return your piece to the exact measurements you requested.

In addition to our technical knowledge and experience, our approach to customer service is grounded in integrity and respect for our industry partners and peers. We will work with you and your team to achieve the necessary results at a reasonable cost.