The Bridgeport Torq-Cut 22 is a smaller CNC vertical machining center. It comes fitted with a grease lubricated and belt driven spindle capable of running up to 7,500 rpm.

Read More

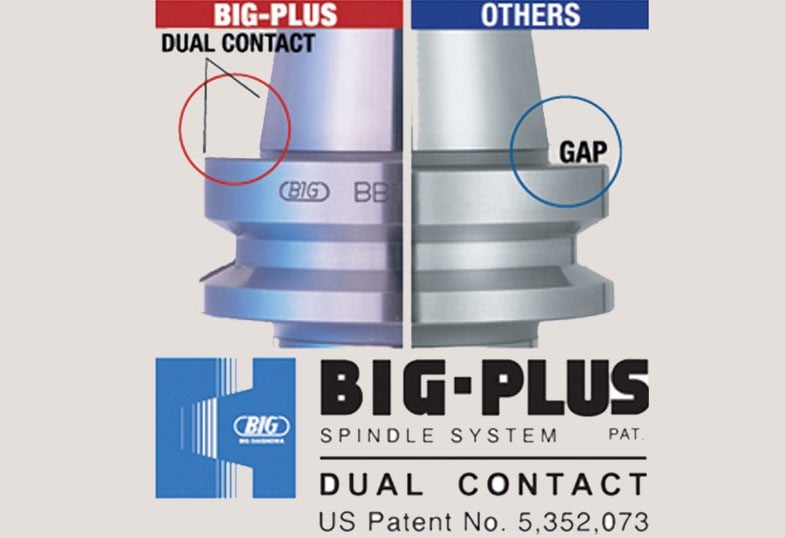

Factory Authorized Big Plus Repair

Ensure maximum performance from your BIG PLUS tooling by having your spindles repaired by Northland Tool & Electronics. To receive the maximum benefit from your BIG PLUS tooling, your spindle must meet the same high quality standards you have come to expect from BIG PLUS. Northland Tool has worked closely with the engineers at BIG Kaiser to develop a repair program exclusively for your BIG PLUS spindles. Special care and attention will be given to the tooling interface, drawbar, bearing journals and balance, ensuring that we provide the extreme accuracy required. The tooling interface will undergo specific quality checks throughout the repair process using only BIG PLUS certified equipment provided to Northland Tool by BIG Daishowa Seiki. Call our sales team with any questions you may have regarding your spindle. We are able to assist you with diagnosing issues over the phone or if needed with our on-site test equipment.

Northland Tool & Electronics is a factory authorized BIG PLUS spindle rebuilder.

Our in house grinding department has over 20 years experience with the close tolerance work required for spindle parts. Northland Tool works closely with BIG Kaiser to ensure the highest quality standards are met with your spindle repair.

TRUSTED BY

It’s a fact of machining — eventually, even top-of-the-line turning machines will experience a spindle failure. Spindles endure tension, torsion, heavy loads, and speeds up to and beyond 150,000 RPM, to name a few of the standard stressors.

Read More