The Bridgeport Torq-Cut 22 is a smaller CNC vertical machining center. It comes fitted with a grease lubricated and belt driven spindle capable of running up to 7,500 rpm.

Read More

Bridgeport Torq-Cut 22 Spindle Repair

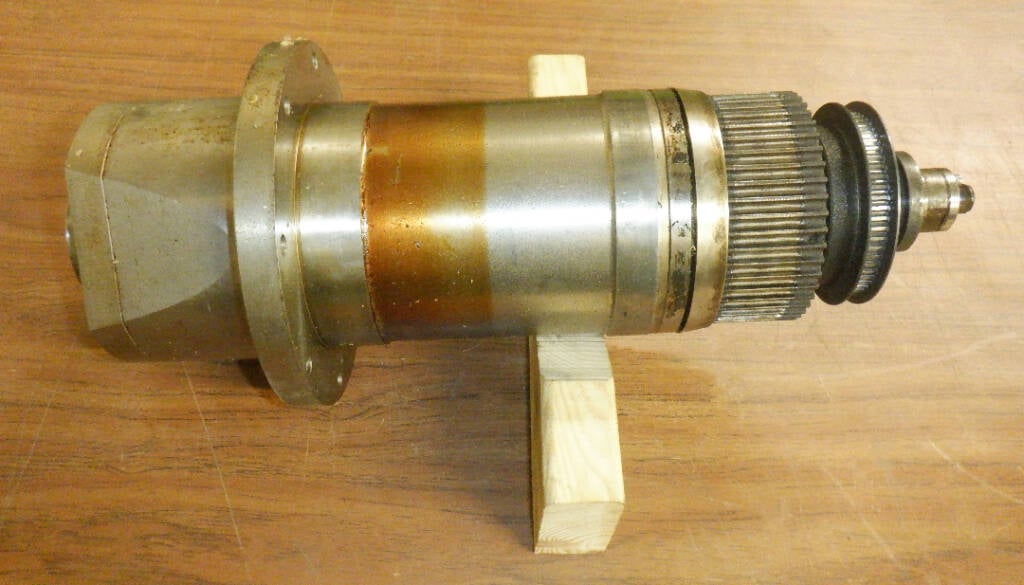

The Bridgeport Torq-Cut 22 is a smaller CNC vertical machining center. It comes fitted with a grease lubricated and belt driven spindle capable of running up to 7,500 rpm. This specific spindle came from the Lee’s Summit, FRC 1987 Broncobots. They are a high school robotics team that manufactures a robot each year for competitions across the country. These competitions include having the robot complete certain tasks like picking up and placing cones/boxes or balancing on a platform. The Broncobots were looking to get the bearings replaced and the taper ground with the end goal of holding tighter tolerances on their parts.

CHALLENGE

We got in contact with the mentor for the Lee’s Summit, FRC 1987 the Broncobots and decided we would help them out with their Bridgeport spindle issues. He stated that the spindle had recently gone out and was in dire need of new bearings and a spindle taper regrind.

Once the spindle arrived at Northland Tool and Electronics we completed a full breakdown and evaluation. We found that the spindle spun by hand but the bearings felt rough and were noisey. The 40 taper id was in poor condition with rust, pock marks, and high run out.

There were multiple broken bellevilles in the drawbar assembly and the outer flange of the encoder pulley was severely bent.

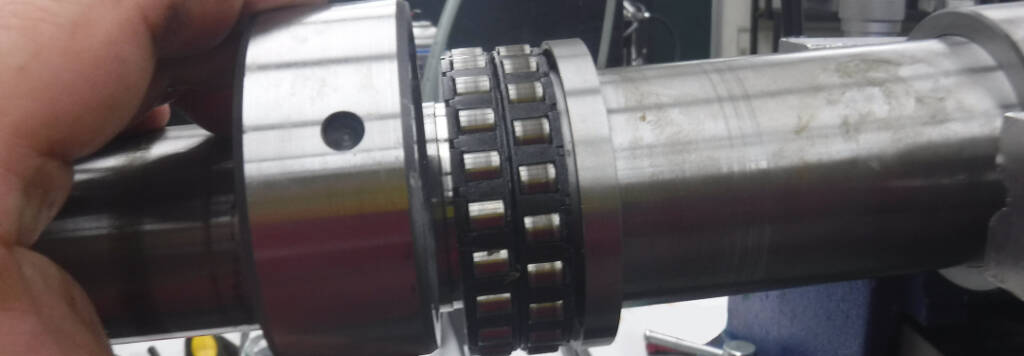

Lastly the rear roller bearing had little to no grease left and the front bearings grease has become discolored from age.

SOLUTION

The following actions were performed on this Bridgeport Torq-Cut spindle:

- Replace all bolts, bearings, orings, bellevilles, and clean entire spindle

- Grind-Plate-Grind the 40 taper ID

- Make new flange ring and install on rear pulley

RESULT

After reassembly of all components, adjusting bearing preload, and undergoing break-in and testing procedures, this spindle passed our final quality inspection and was returned to the FRC 1987 Broncobots with a 1-year warranty.

A note from the Mentor of the Broncobots:

“It has been quite the successful season for the team as we won both of the local regionals that we competed at; both in Olathe, KS and at our home event we hosted at our high school. The rebuilt spindle definitely contributed to our success this year as the students decided to pursue a complex design that required tight fits between different components on our robot’s telescoping arm which I was able to help them execute much more easily than in past years.”

Does your spindle need repair? GET A QUOTE TODAY

More Case Studies

Repair History - Here are examples of similar spindle repairs that may contain additional information that will help you. If you have additional questions, please contact us.

It’s a fact of machining — eventually, even top-of-the-line turning machines will experience a spindle failure. Spindles endure tension, torsion, heavy loads, and speeds up to and beyond 150,000 RPM, to name a few of the standard stressors.

Read More