GPG: Grind-Plate-Grind Process Explained

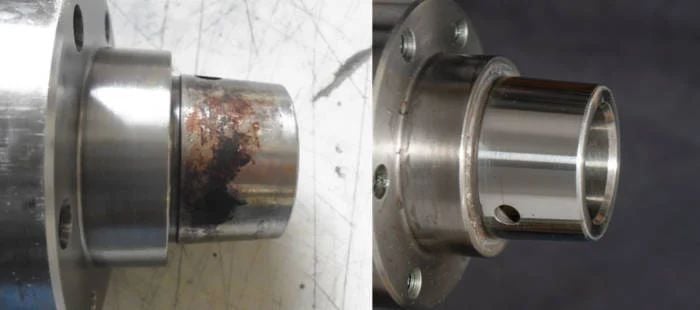

When a cylindrical surface, such as the OD of a shaft or the ID of a tooling taper, becomes worn or damaged, we use a process referred to as grind-plate-grind (GPG) to restore dimensions to original OEM specification. First, we pre-grind, also referred to as “green grind,” to remove a thin layer of material and smooth any damage. Next, the part undergoes an electroplating process to apply a layer of hard chrome to the desired area. This builds up a durable surface that is slightly oversized than the final desired dimension. Finally, the part goes on the grinder again for a finish grind to remove excess chrome until it reaches the target dimension.

Why chrome?

- Superior Hardness: Chrome is exceptionally hard and durable. For spindle components, hard chrome is the best choice for parts that will function well under continued use and last for a long time.

- Lower Coefficient of Friction: Hard chrome is ideal for moving parts. It has a low coefficient of friction, which means it’s easier for things to move along it. It also retains oil well, which improves performance.

NTE has in-house OD & ID grinding capabilities to pre-grind and finish grind damaged cylindrical components to micron-level specifications. We use an outside resource for hard chrome plating due to the complexity of the electroplating process and the environmental concerns that go along with handling the chemicals involved. Through maintaining a close working relationship with our chroming vendor we are able to deliver on tight turnaround times for our customers.

- Machine Tool Spindle Bearing Lubrication: What To Know

- Delaying Spindle Service Causes More Damage, Costly Repairs

- What Does It Mean to Be a Factory Authorized Big Plus Spindle Rebuilder?

- Precision Machining in a World of Microns

- GPG: Grind-Plate-Grind Process Explained

- What Is the Spindle Repair Process?