Precision Machining in a World of Microns

How small is a micron, and why do we work in such a small scale?

Precision is defined as the quality, condition, or fact of being exact and accurate. But how close is “exact”, exactly? It all depends on the application. There is no clearly defined tolerance range for a workpiece to be considered “high precision,” but in our line of work repairing spindles, we frequently encounter specs calling for a tolerance of +/- 2 microns.

A micron (μm), or micrometer, is one millionth of a meter, or 1/25,400th of an inch. That’s roughly 0.00004″. For comparison, in common machining terminology, a “thou” refers to thousandths of an inch, or .001″, which is equal to 25.4 μm.

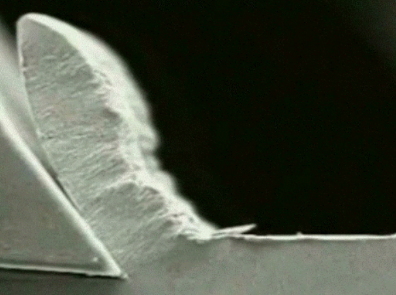

So, how small is a micron? The micron is a common unit of measurement for wavelengths of infrared radiation as well as sizes of cells and bacteria. Here are some examples of relative particle sizes of common materials:

- Human hair: 50-100 μm

- Dust mite: 3-10 μm

- Fungal spores: 0.5–7 μm

- Beach sand: 100-2000 μm

- Eye of a needle: 1230 μm

- Red blood cell: 6-8 μm

- Spider web: 2-3 μm

- Human vision: 40 μm

(visible to the naked-eye)

Why do we work to micron-level tolerance?

Our customers represent a wide range of industries, and they use machines to manufacture components that will be used in aerospace, defense, and medical applications, so their machines must be capable to consistently produce highly precise parts.

A machine’s accuracy is highly dependent upon the health of the machine tool spindle, which must operate within specifications from the OEM. Continued use over time, or damage after a machine crash, will require a spindle rebuild. When we receive a spindle to be rebuilt, we take measurements of all critical dimensions and apply a grind/chrome-plate/finish grind process to bring dimensions back to OEM specification. Our in-house grinding department can hold micron-level tolerance, ensuring that your rebuilt spindle will operate as good as new.

When your spindle fails, contact the experts at Northland Tool, where we live in a world of microns. Click here to send us your spindle today.

- Machine Tool Spindle Bearing Lubrication: What To Know

- Delaying Spindle Service Causes More Damage, Costly Repairs

- What Does It Mean to Be a Factory Authorized Big Plus Spindle Rebuilder?

- Precision Machining in a World of Microns

- GPG: Grind-Plate-Grind Process Explained

- What Is the Spindle Repair Process?