The Bridgeport Torq-Cut 22 is a smaller CNC vertical machining center. It comes fitted with a grease lubricated and belt driven spindle capable of running up to 7,500 rpm.

Read MoreSpindle Repair, Remanufacturing & Rebuilding

Northland Tool specializes in Spindle Repair

Northland Tool & Electronics is your go-to solution for precision spindle repair and rebuilding. Whether your spindle needs emergency service or routine maintenance, our team of technicians draws upon 40+ years of spindle rebuilding experience to get your operations back up and running with the least amount of machine downtime.

SPINDLE REPAIR PROCESS

Evaluation

- Upon arrival, we log every spindle into our production tracking software system and any issues associated with transit are noted.

- Our technicians then carefully break down the spindle into its component parts, note their general condition as well as specific damage, and perform a full dimensional inspection to identify excessive wear.

- Our production manager performs a second evaluation, during which he/she will try to identify the cause of failure, consult with the head of our grinding and machining departments, and determine any recommendations for preventative measures.

Quote & Scheduling

- Our purchasing department sources all replacement part costs, determines lead times, and generates a quote.

- Our team gives the quote a final check and communicates it to the customer for approval.

- Following the customer’s approval, we schedule production and order any parts needed for the repair.

Assembly & Delivery

- We carefully clean all parts of the spindle and complete any necessary grinding or machining operations.

- Our highly trained technicians then assemble all spindle components and perform a rigorous break-in process. This includes dynamic balancing and thermal/vibration analysis.

- After our inspectors perform a final quality control check, our shipping department carefully boxes the spindle and returns it to the customer.

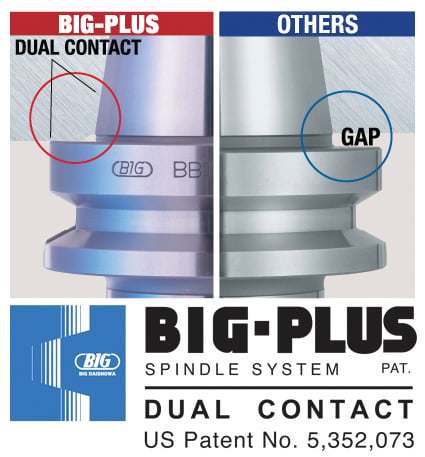

Our team has worked closely with the engineers at BIG Kaiser to develop a repair program exclusively for BIG-PLUS® spindles, so we can ensure maximum performance following any BIG-PLUS® repair. We give special care and attention to the tooling interface, drawbar, bearing journals, and balance, delivering the extreme accuracy that’s required.

We perform specific quality checks on the tooling interface throughout the repair process using only BIG-PLUS® certified equipment provided by BIG Daishowa Seiki.

We address the drawbar as part of every spindle repair we perform (if applicable). We ask that customers include all rotating parts when sending in their spindle, including the drawbar system. We like to balance the entire rotating assembly to ensure we achieve the best possible spindle lifespan. Once we verify that the drawbar system is functioning properly and has the correct tool holding force, we know your spindle will perform at its best.

Our Spindle Repair Equipment

Our repair shop is stocked with the specialized equipment needed to repair most types of spindles. We also utilize four Kellenberger 1000U cylindrical grinding machines to repair any dimensional deviations found during the repair process.

We own hundreds of precision testing tools that help us guarantee a quality repair every time. These include:

- Vibration analyzers: We test run (when possible) and balance using vibration analysis for spindles we repair. Vibration analysis provides us with data on the bearing health, balance, and acceleration. This data helps us confirm the spindle is healthy and can perform up to the high standards NTE holds.

- Air gauges: Northland Tool uses air gauges to make sure any taper repairs we perform have proper tool contact.

- Test bars: Test bars are used to ensure every spindle leaves with less than two microns of runout.

- Motor analyzers: A highly advanced Motor Analyzer test ensures that all stators and rotors are in perfect working order before they leave our facility.

- Force gauges: Force guages are used to test the drawbar pullforce for incoming and outgoing spindles

- Oscilloscopes: Used to test various sensors on spindles.

- 3 point dynamic runout tester: Used to measure runout while the spindle is running at various RPM’s.

- Load cells: Used to measure the actuation force of a drawbar

…and all other measuring equipment associated with a high-end metrology room. We’ve made major investments in our testing equipment so we can stand head and shoulders above other spindle repair providers.

When you choose Northland Tool for your routine or emergency spindle repair, you’re guaranteed fast turnaround times, exceptional customer service, and decades of experience. Our pricing and lead times are extremely competitive, so you can be confident you’re receiving expert service at a reasonable cost with minimal downtime.

Thanks to our knowledgeable team and grinding department, we rarely need to rely on outside vendors. We perform all work at our shop in Weare, New Hampshire, where we’ve gained the trust of manufacturing partners like Lockheed Martin, The Triumph Group, and General Dynamics.

We’ve seen a lot of spindles in our 40+ years of spindle rebuilding, and a lot of spindle issues — often avoidable ones. Along with a detailed report for every repair, we can recommend proper maintenance, routine checks, and preventative measures that could extend the life of your spindle and help you avoid costly downtime due to an avoidable issue.

As part of our ongoing customer relationships, we offer spindle care seminars, vibration analysis, contamination prevention analysis, cause of failure tracking, spindle upgrades, and much more.

Our competitive 1 Year Warranty policy ensures that proper workmanship and parts free of defect are used in the repairing or rebuilding of every spindle. The warranty begins as soon as the repaired spindle is shipped from Northland Tool, and is valid for a period of 12 months thereafter. We will replace any parts that prove to be defective under normal use and correct any improper workmanship at no charge to the customer.

It’s a fact of machining — eventually, even top-of-the-line turning machines will experience a spindle failure. Spindles endure tension, torsion, heavy loads, and speeds up to and beyond 150,000 RPM, to name a few of the standard stressors.

Read More