How to Recognize Bad Spindle Symptoms

It’s a fact of machining — eventually, even top-of-the-line turning machines will experience a spindle failure.

It’s a fact of machining — eventually, even top-of-the-line turning machines will experience a spindle failure.

The success of any precision machinery relies heavily on various intricate components working seamlessly in unison.

Downtime is inevitable for any machine, but knowing how to reduce downtime or minimize its likelihood is critical.

One of the most valuable tools for identifying spindle issues is sound.

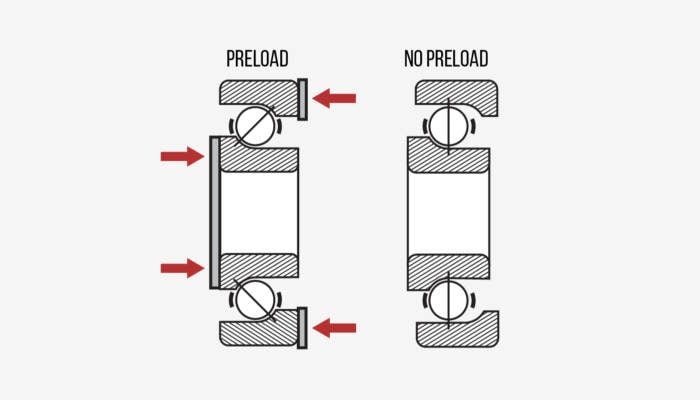

In this helpful guide to spindle bearing preload, Northland Tool & Electronics will answer all the basic questions about your spindle bearing preload calculations.

In machining, runout refers to inaccuracies in a tool or piece of equipment that cause it to spin off its ideal axis.