ABEC Bearing Ratings & Scale Guide: Everything You Need To Know

What Are ABEC Ratings?

The Annular Bearing Engineering Committee (ABEC) was founded over 50 years ago to establish acceptable tolerances and specifications for the size and geometric accuracy of all bearings. The tolerance level of a ball bearing is referred to as an ABEC rating.

The ABEC rating scale is the accepted standard for tolerances of a ball bearing. The scale displays five levels from widest to tightest tolerances: 1, 3, 5, 7, and 9. The higher the ABEC class the better the precision, efficiency, and speed capabilities of the bearing. Bearings that do not meet at least ABEC 1 standards cannot be classified as precision bearings since their tolerances are too loose.

High rated ABEC bearings (ABEC 5, 7, 9) are intended for precision applications like aircraft instruments, machine tools, and surgical equipment. Lower graded ABEC bearings (ABEC 1 and 3) are intended for most other applications requiring ball bearings, including vehicles, skateboards, mechanical hobbies, fishing reels, etc.

ABEC Rating Charts

Save the following charts so you have them on hand for your next replacement or repair.

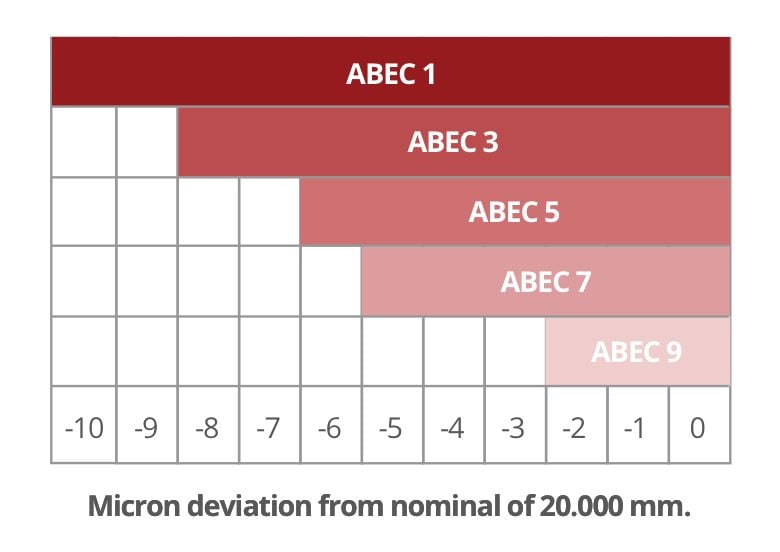

ABEC Bearing Tolerances

The differences in tolerance per ABEC class in micrometers (µm) for a 20 mm inner diameter bearing. As shown, a 20 mm ABEC 7 bearing only has a 5 μm tolerance window, whereas an ABEC 1 has a tolerance that is twice that width.

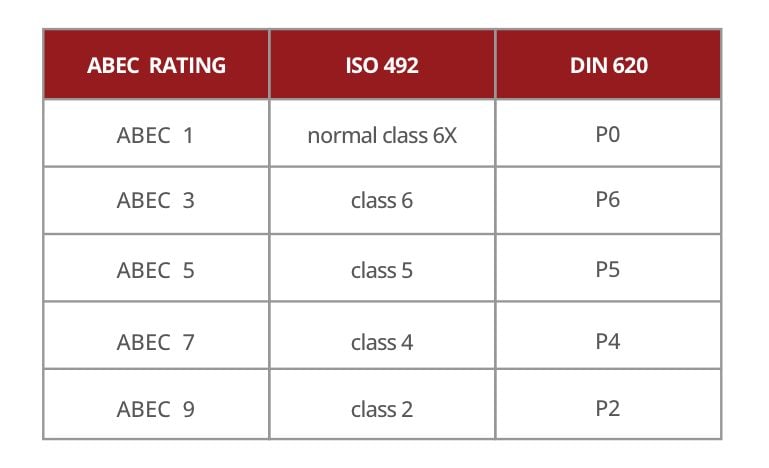

ABEC Scale vs. ISO/DIN

This chart displays the ABEC ratings equivalent to the ISO 492 (and the German DIN 620) for bearing tolerances.

How to Choose Bearings with the Right ABEC Rating

The ABEC rating for your spindle bearings is a very important factor. At Northland Tool and Electronics we only use bearings that are rated at ABEC 7 or higher. This is due to the extremely tight tolerances required by the spindles we service. A bearing that is too loose for its application can cause an imbalance of the load at high speed or impact the maximum torque, which reduces its life span. On the other hand, bearings that are rated higher than necessary can significantly impact the cost of overall operation.

If you are trying to source bearings for your own spindle, double check that the bearings you wish to purchase meet the appropriate specifications for your application. Sometimes simply using the part number from the old bearing is not enough. When specifying replacement bearings for our spindle repairs we take many factors into account before choosing a particular part number.

If you have any questions about your ABEC rating, we would be happy to point you in the right direction. We have vast experience with many reputable bearing manufacturers, so send us a note today.

- Machine Tool Spindle Bearing Lubrication: What To Know

- Delaying Spindle Service Causes More Damage, Costly Repairs

- What Does It Mean to Be a Factory Authorized Big Plus Spindle Rebuilder?

- Precision Machining in a World of Microns

- GPG: Grind-Plate-Grind Process Explained

- What Is the Spindle Repair Process?