What Does It Mean to Be a Factory Authorized Big Plus Spindle Rebuilder?

The ability to rebuild a BIG PLUS spindle is a specialty few spindle repair companies possess. In fact, BIG PLUS spindle rebuilds are such a rare attribute that only nine operations in North America are licensed and authorized as “BIG PLUS spindle rebuilders.”

The reason so few operations possess these credentials is because working on BIG PLUS tooling requires special care and attention, in addition to extreme accuracy and precision.

But what is a BIG PLUS spindle, and what does it really mean to be a licensed and factory-authorized BIG PLUS spindle rebuilder? Let’s have a look:

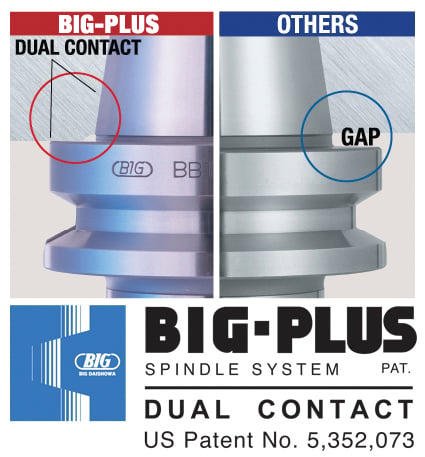

BIG PLUS is a spindle system that provides dual contact between a spindle face and a flange face of BIG PLUS tooling. (For more information on spindle related terminology, click here). This unique tool holding technology increases surface contact with a tool holder, thereby maximizing rigidity and clamping pressure.

“There is a significant advantage in tool life, accuracy and cutting capability when compared to standard tool holders.”

— BIG Kaiser Precision Tooling Inc.

In order for a shop to be granted a BIG PLUS license, it must demonstrate that special care and attention will be given to the tooling interface, drawbar, bearing journals and balance. A BIG PLUS spindle rebuilder must also ensure that they provide the extreme accuracy required of all factory-authorized BIG PLUS rebuilders.

At Northland Tool & Electronics, we have worked closely with the engineers at BIG Kaiser to develop a repair program exclusively for BIG PLUS spindles. As one of only a select few factory authorized BIG PLUS spindle rebuilders in North America, we at Northland use only BIG PLUS certified equipment provided to Northland Tool by BIG Daishowa Seiki.

Contact our sales team with any questions you may have regarding your BIG PLUS spindle repair. We are also able to assist you with diagnosing issues over the phone or, if needed, with our on-site test equipment.

- Machine Tool Spindle Bearing Lubrication: What To Know

- Delaying Spindle Service Causes More Damage, Costly Repairs

- What Does It Mean to Be a Factory Authorized Big Plus Spindle Rebuilder?

- Precision Machining in a World of Microns

- GPG: Grind-Plate-Grind Process Explained

- What Is the Spindle Repair Process?