The Bridgeport Torq-Cut 22 is a smaller CNC vertical machining center. It comes fitted with a grease lubricated and belt driven spindle capable of running up to 7,500 rpm.

Read More

Famu PHS-912 FIVE Gruppo Parpas Spindle Repair

CHALLENGE

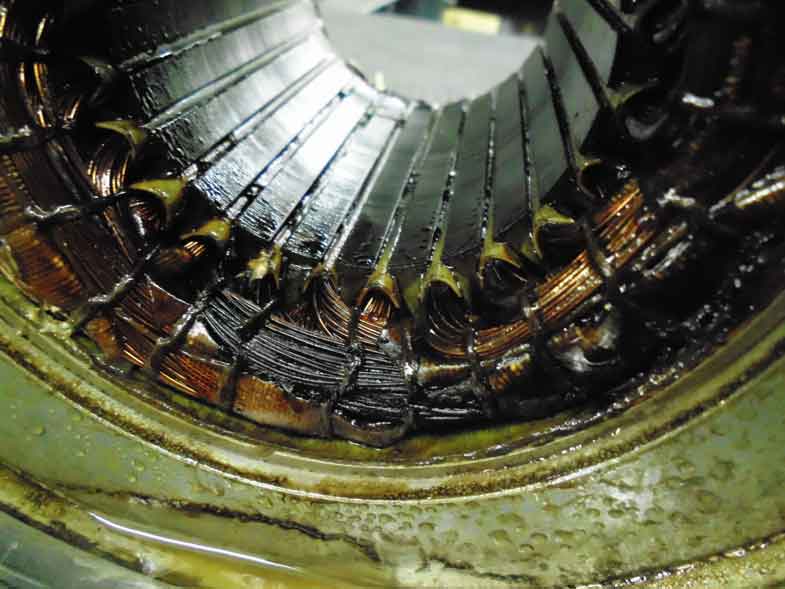

This two-axis milling head was factory-installed on a Famu PHS-912 FIVE machine by the Italian manufacturer Gruppo Parpas. Our customer indicated that a coolant component had failed, flooding the spindle which caused the drive to trip the machine off. Our inspection showed that one phase of the stator had burned out. We also determined that the bearing grease had been severely contaminated, and that spindle had several significant dimensional issues as well.

SOLUTION

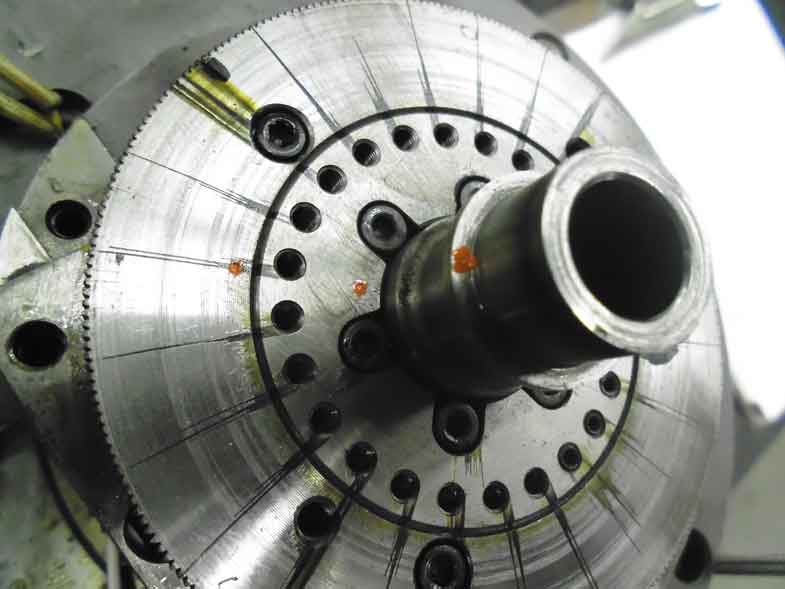

Our comprehensive plan of action started with a stator rewind. We also performed several grind, chrome plate, and finish grind operations to correct severe egging of the rear bearing housing ID and OD, fretted and undersized front and rear bearing journals, excessive runout of the HSK32 taper and face, and brinelling of the ball cage housing ID. We balanced the spindle shaft with all installed components on our Schenck machine, and then reassembled the spindle with the rewound stator and the precision ground components. We installed new ceramic bearings, Belleville springs, tool gripper fingers, o-rings, and assembly screws.

RESULT

After reassembly of all components, adjusting bearing preload, and undergoing break-in and testing procedures, this spindle passed our final quality inspection before being returned to our customer with a 1-year warranty.

DETAILED CAUSE OF FAILURE

Does your spindle need repair? GET A QUOTE TODAY

More Case Studies

Repair History - Here are examples of similar spindle repairs that may contain additional information that will help you. If you have additional questions, please contact us.

It’s a fact of machining — eventually, even top-of-the-line turning machines will experience a spindle failure. Spindles endure tension, torsion, heavy loads, and speeds up to and beyond 150,000 RPM, to name a few of the standard stressors.

Read More