The Bridgeport Torq-Cut 22 is a smaller CNC vertical machining center. It comes fitted with a grease lubricated and belt driven spindle capable of running up to 7,500 rpm.

Read More

Kitamura Mycenter 4XD Spindle Repair

The Kitamura Mycenter 4XD vertical machining center is equipped with a high-power (35-HP) spindle capable of running up to 12,000 rpm.

CHALLENGE

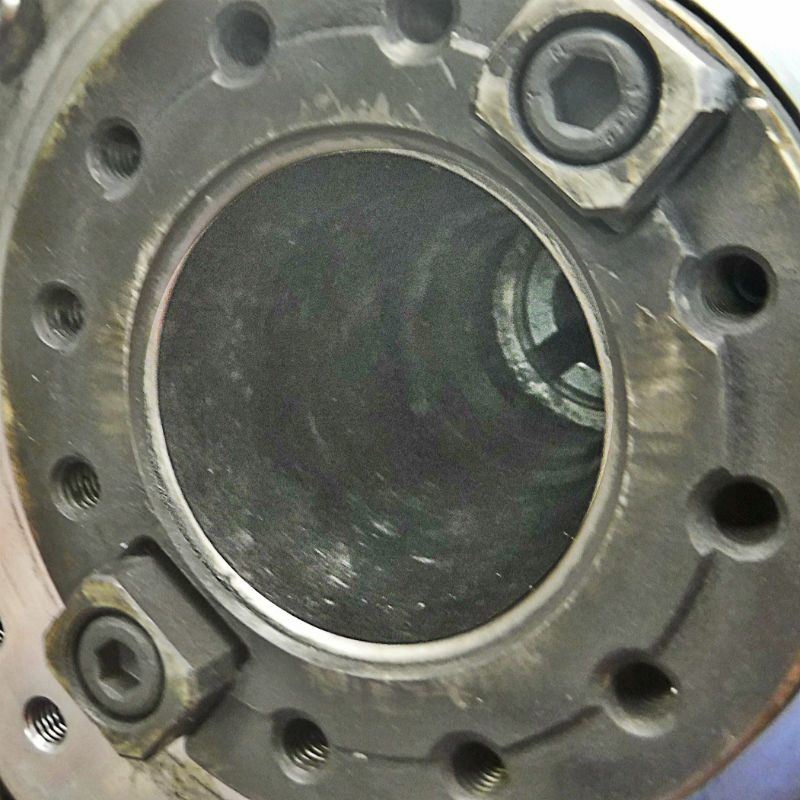

Our customer experienced a machine crash that caused severe damage to the spindle. They sent a second, identical spindle in case we could reuse parts to expedite the rebuild. Upon initial inspection, our technician noted that the tooling taper ID had significant surface damage. The ceramic bearings sounded fine when rotated by hand, but some coolant contamination was found and it was recommended that these should be replaced. The drawbar assembly and grippers were in good condition, and tool retention force was adequate. All critical dimensions were found to be within tolerance of specifications (bearing journals/shoulders, housing bores).

SOLUTION

After our assessment and customer approval to proceed with the rebuild, all parts to be reused were thoroughly cleaned.

We performed a kiss grind to the tooling taper ID to smooth the surface damage. We replaced NSK ceramic bearings, o-rings, and assembly screws.

RESULT

After reassembly of all components, adjusting bearing preload, and undergoing break-in and testing procedures, this spindle passed our final quality inspection before being returned to our customer with a 1-year warranty.

DETAILED CAUSE OF FAILURE

Does your spindle need repair? GET A QUOTE TODAY

More Case Studies

Repair History - Here are examples of similar spindle repairs that may contain additional information that will help you. If you have additional questions, please contact us.

It’s a fact of machining — eventually, even top-of-the-line turning machines will experience a spindle failure. Spindles endure tension, torsion, heavy loads, and speeds up to and beyond 150,000 RPM, to name a few of the standard stressors.

Read More