Jesse Riccardi

General ManagerWith over 15 years of spindle rebuilding experience, training, and shop management, Jesse specializes in partnering with industry leaders to advance and improve the precision machine service market.

It’s a fact of machining — eventually, even top-of-the-line turning machines will experience a spindle failure.

The success of any precision machinery relies heavily on various intricate components working seamlessly in unison.

Downtime is inevitable for any machine, but knowing how to reduce downtime or minimize its likelihood is critical.

One of the most valuable tools for identifying spindle issues is sound.

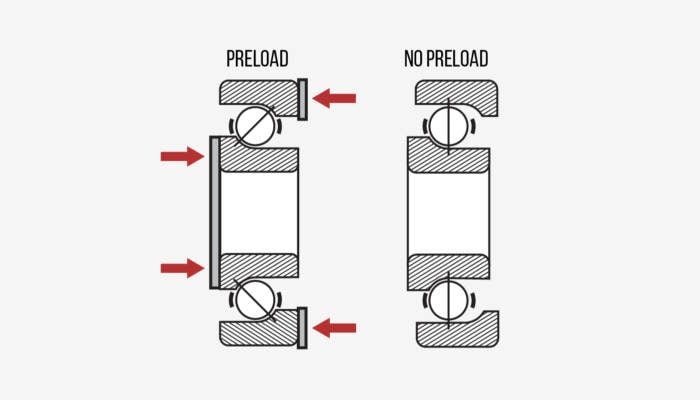

In this helpful guide to spindle bearing preload, Northland Tool & Electronics will answer all the basic questions about your spindle bearing preload calculations.

There are many benefits of a ceramic conversion program by Northland Tool & Electronics, including: Service: Our staff will be in contact with you all the way through the spindle repair process, a…