The Bridgeport Torq-Cut 22 is a smaller CNC vertical machining center. It comes fitted with a grease lubricated and belt driven spindle capable of running up to 7,500 rpm.

Read More

Citizen L20 Spindle Repair

The Citizen L20 is a swiss style CNC turning center. It can come fitted with this grease lubricated and belt driven spindle capable of running up to 10,000 rpm.

CHALLENGE

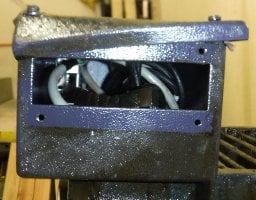

This Citizen L20 spindle was sent in with our customer complaining of it sounding loud. The spindle felt rough when spun by hand when it arrived at Northland Tool and Electronics. We noted right away that a corner of the electrical box cover was bent and curved over the box. We also measured high runouts on the pilot OD, face, and tail incoming. After completing a full breakdown and evaluation, we found that the bearings were severely contaminated with grinding swarf and appear to have suffered some heat damage. The rear journal and shoulder had high run out bareshaft and was very close to being out of ISO spec in size. Runouts remained high on pilot OD and Face bareshaft. Lastly, the bronze bushings appeared to be in good shape. No other dimensional deviations were noted for this repair.

SOLUTION

The following actions were performed on this Citizen L20 spindle:

- Clean, inspect overall dimensions

- Replace bolts, seals, and bearings

- Grind, chrome plate, and finish grind the rear bearing journal

- Kiss grind pilot OD and face

- Flatten the electrical box cover

RESULT

After reassembly of all components, adjusting bearing preload, and undergoing break-in and testing procedures, this spindle passed our final quality inspection before being returned to our customer with a 1-year warranty.

DETAILED CAUSE OF FAILURE

Does your spindle need repair? GET A QUOTE TODAY