The Bridgeport Torq-Cut 22 is a smaller CNC vertical machining center. It comes fitted with a grease lubricated and belt driven spindle capable of running up to 7,500 rpm.

Read More

Studer S-50-4 Spindle Repair

CHALLENGE

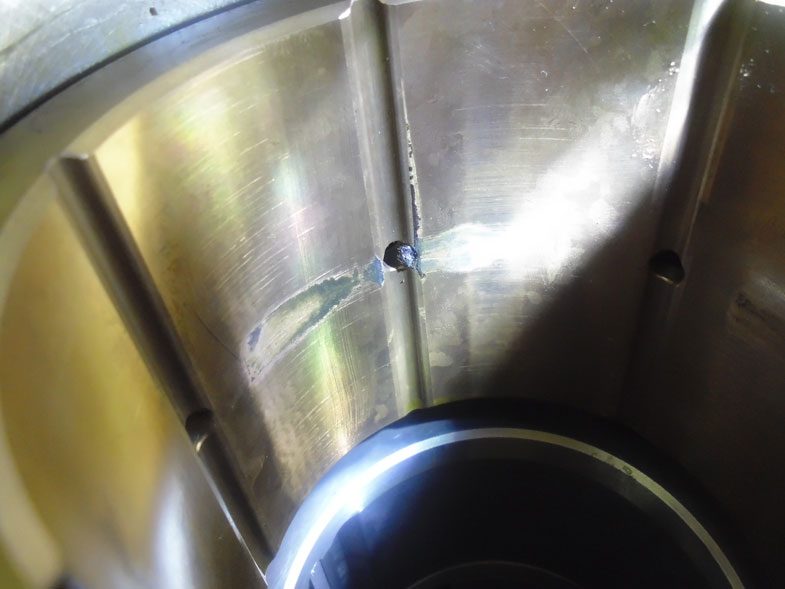

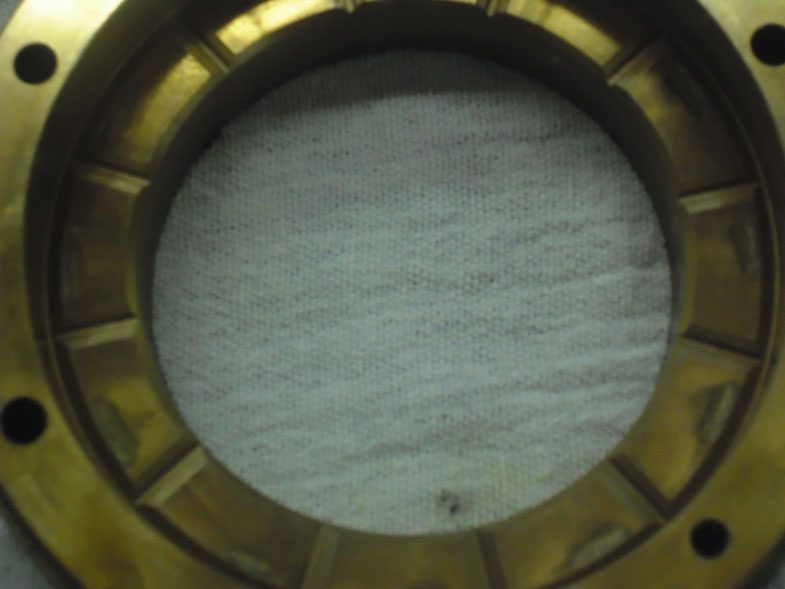

Our customer indicated that this OD grinding spindle had locked up during operation. Upon inspection, we found that a lump of grinding swarf had penetrated the spindle interior through an incoming oil port. This particulate became lodged in the area between the ID of the rear bronze bearing and the OD of the spindle shaft. The rotation of the shaft smeared the particulate onto the ID of the bronze bearing, scarring it while also causing the shaft to rub out on the front bronze bearing and the thrust bearing.

SOLUTION

Because the radial bronze bearings in this spindle are designed as tapered lobes, we could not rework the bearings on one of our Kellenberger cylindrical grinders. Our course of action was to rescrape the three bearings by hand so that the spindle oil would create the proper hydrodynamic film. The tolerance for radial motion at the front & rear bronze bearings had to be between 4 and 6 microns, while the thrust bearing had to limit axial motion to less than 4 microns. Fortunately, the spindle shaft was not damaged and required no attention. Because we did not receive the entire wheelhead assembly, we could not test run the spindle.

RESULT

This spindle passed our final quality inspection before being returned to our customer with a 1-year warranty. On follow up, our customer reported that the spindle was functioning better than when it was first installed.

DETAILED CAUSE OF FAILURE

Does your spindle need repair? GET A QUOTE TODAY

More Case Studies

Repair History - Here are examples of similar spindle repairs that may contain additional information that will help you. If you have additional questions, please contact us.

It’s a fact of machining — eventually, even top-of-the-line turning machines will experience a spindle failure. Spindles endure tension, torsion, heavy loads, and speeds up to and beyond 150,000 RPM, to name a few of the standard stressors.

Read More