The Bridgeport Torq-Cut 22 is a smaller CNC vertical machining center. It comes fitted with a grease lubricated and belt driven spindle capable of running up to 7,500 rpm.

Read MoreCAMPBELL SPINDLE REPAIR

With over 40 years of spindle rebuilding experience, the team at Northland Tool & Electronics can rebuild a wide range of spindles with the precision required to do the job right.

Campbell Grinder Company in Spring Lake Michigan is one of the few remaining manufacturers of quality grinding equipment in the United States today. Northland Tool & Electronics can rebuild Campbell spindles to the highest level of precision and accuracy customers have come to expect from their Campbell machines.

Your repair will be completed by factory trained spindle professionals in our facility built specifically for the process of spindle repair. Grinding work will be performed in our own grinding department, which works closely with our assembly technicians to make sure the dimensional work is to the highest standard possible.

Common Campbell Issues

From coolant contamination to bearing failure to crashes, Northland knows that there are a variety of issues that can affect the performance of your spindle, and we’re prepared to handle them all. Some common issues that Campbell spindles encounter include:

- Bearing failure (very common)

- Contamination

- Damage from crash

- Worn tooling threads

- Worn labyrinths, allowing coolant to migrate to the bearings

- Worn bearings

- Worn tooling interfaces

Campbell Case Studies

Spindle Repair Process

-

Evaluation

-

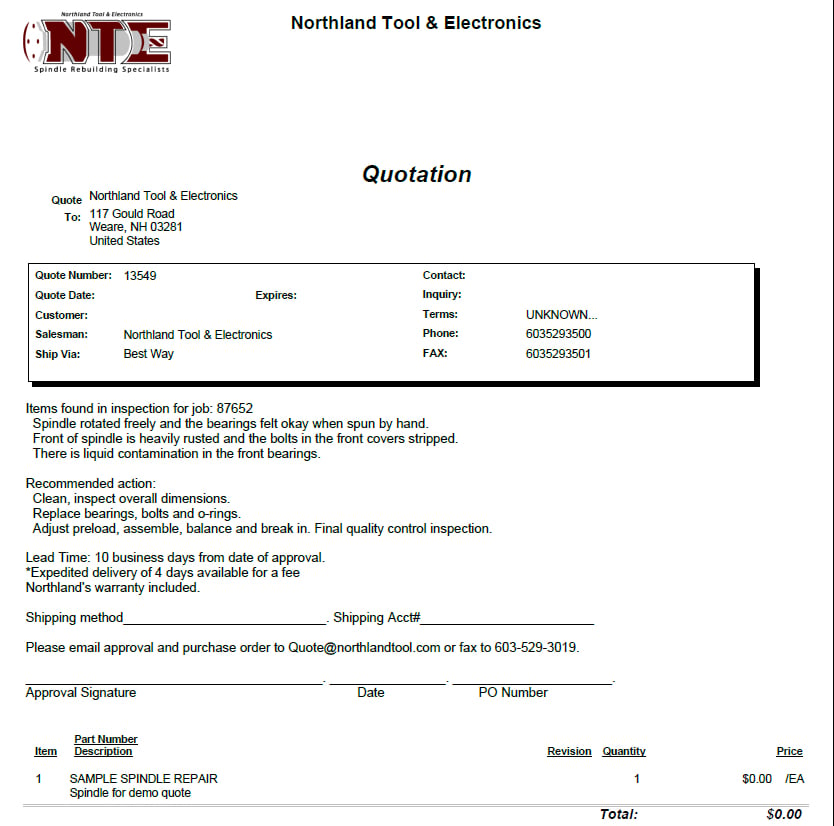

Quote & Scheduling

-

Assembly & Delivery

- Upon arrival, we log every spindle into our production tracking software system. Any issues associated with transit are noted.

- Our technicians carefully break down the spindle into its component parts, note their general condition as well as specific damage and perform a full dimensional inspection to identify excessive wear.

- Our production manager performs a second evaluation, during which he/she will identify the mode of failure, consult with the head of our grinding and machining department and determine recommendations for future preventative measures.

- Our purchasing department sources all replacement part costs, determines lead times and generates a quote.

- Our team gives the quote a final check and communicates it to the customer for approval.

- Following customer approval, we schedule production and order the parts needed.

- Once we receive the parts, we carefully clean them and complete any necessary grinding or machining operations.

- Our highly trained technicians assemble all spindle components and perform a rigorous break-in process. This may include dynamic balancing and thermal and vibration analysis.

- After our inspectors perform a final quality control check, our shipping department carefully boxes the spindle and returns it to the customer.

1 Year Warranty

Our competitive 1 Year Warranty policy ensures that proper workmanship and parts free of defect are used in the repairing or rebuilding of every spindle. The warranty begins as soon as the repaired spindle is shipped from Northland Tool, and is valid for a period of 12 months thereafter. We will replace any parts that prove to be defective under normal use and correct any improper workmanship at no charge to the customer. Please see our full warranty terms for more details.

It’s a fact of machining — eventually, even top-of-the-line turning machines will experience a spindle failure. Spindles endure tension, torsion, heavy loads, and speeds up to and beyond 150,000 RPM, to name a few of the standard stressors.

Read More