The Bridgeport Torq-Cut 22 is a smaller CNC vertical machining center. It comes fitted with a grease lubricated and belt driven spindle capable of running up to 7,500 rpm.

Read More

Hardinge Bridgeport VMC1000 P3 poorly rebuilt by another spindle repair company

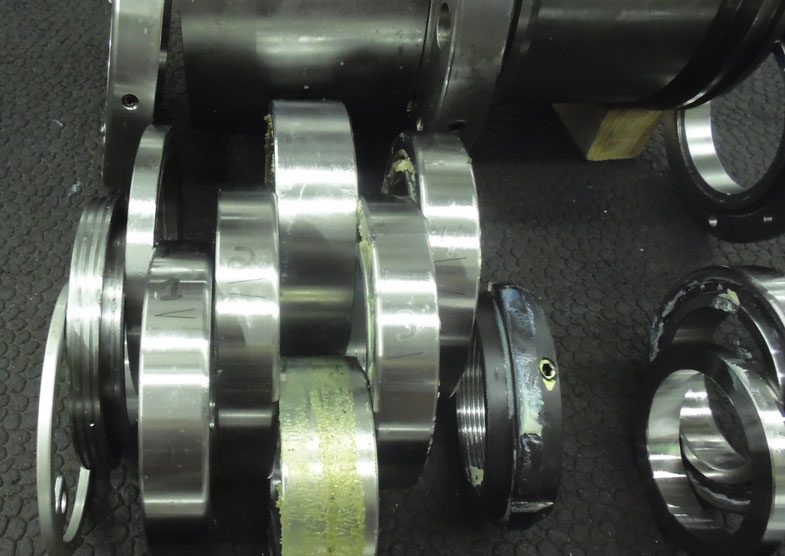

Our customer sent us this Hardinge Bridgeport VMC1000 P3 spindle without the drawbar assembly and some of the rear rotating components. They did this because this is their spare spindle for a population of three of these machines. They indicated that the spindle became very tight and hard to turn after being rebuilt elsewhere and then ran for about eight months. They also stated that they believed coolant contamination of the bearings is to blame for the consistently short lifespan of the spindles on these machines.

CHALLENGE

When we evaluated the spindle, we noted that the front-most #1 bearing of the quad set had suffered a catastrophic failure. We partially confirmed the customer’s suspicion as the grease in the #2 & #3 bearings was contaminated with coolant. However, we also noted an excessive amount of lightly-discolored grease which had extruded from the between the races of the rear-most #4 bearing. The previous rebuilder may well have over-lubricated the quad set, which will lead to friction as the bearings try to plow through the excessive amount of grease. The heat from this friction will eventually cause bearing failure.

SOLUTION

The following actions were performed on this Hardinge Bridgeport VMC1000 P3 spindle:

- Clean all parts of the spindle

- Replace all bolts and o-rings

- Replace bearings

RESULT

After reassembly of all components, adjusting bearing preload, and undergoing break-in and testing procedures, this spindle passed our final quality inspection before being returned to our customer with a 1-year warranty.

DETAILED CAUSE OF FAILURE

Does your spindle need repair? GET A QUOTE TODAY

More Case Studies

Repair History - Here are examples of similar spindle repairs that may contain additional information that will help you. If you have additional questions, please contact us.

It’s a fact of machining — eventually, even top-of-the-line turning machines will experience a spindle failure. Spindles endure tension, torsion, heavy loads, and speeds up to and beyond 150,000 RPM, to name a few of the standard stressors.

Read More