Northland Tool & Electronics repairs many types of Hardinge spindles, including:

HARDINGE SPINDLE REPAIR

We work closely with Hardinge to provide our customers with the most comprehensive independent Hardinge spindle repair available. We stay up to date on current Hardinge spindle designs to ensure we know how to best improve their lifespan.

Types of Hardinge Spindles Repaired

Hardinge Common Issues

From coolant contamination to bearing failure to crashes, Northland knows that there are a variety of issues that can affect the performance of your spindle, and we’re prepared to handle them all. Some common issues that Hardinge spindles encounter include:

- Bearing failure

- Contamination

- Damage from crash

- Fretting housing

- Housing out of ISO

- Journal out of ISO

- Worn tapers

Hardinge Case Studies

-

GX 300

-

VMC 1250

-

VMC1000 P3

-

C42

-

Conquest T42

-

Conquest T42 Sub

-

Conquest-SG-2

-

DT-480P3

-

Elite 6/42

-

Quest 6/42

-

Quest 8/51

-

SV150

-

Spindle

-

VMC 1000

-

VMC 1500 P3

-

VMC 1500XP3

-

VMC 600 II

-

VMC 600P3

-

VMC800II

-

XV 710

-

GTA 1353-B

-

GX510

-

GX600

-

LC-1220

-

QC 201BL

-

Quest 42

-

TT-65

-

Talent 8/52

-

Hardinge Cobra 51

-

Hardinge GX 1000 OSP

-

Hardinge V1000

Spindle Repair Process

-

Evaluation

-

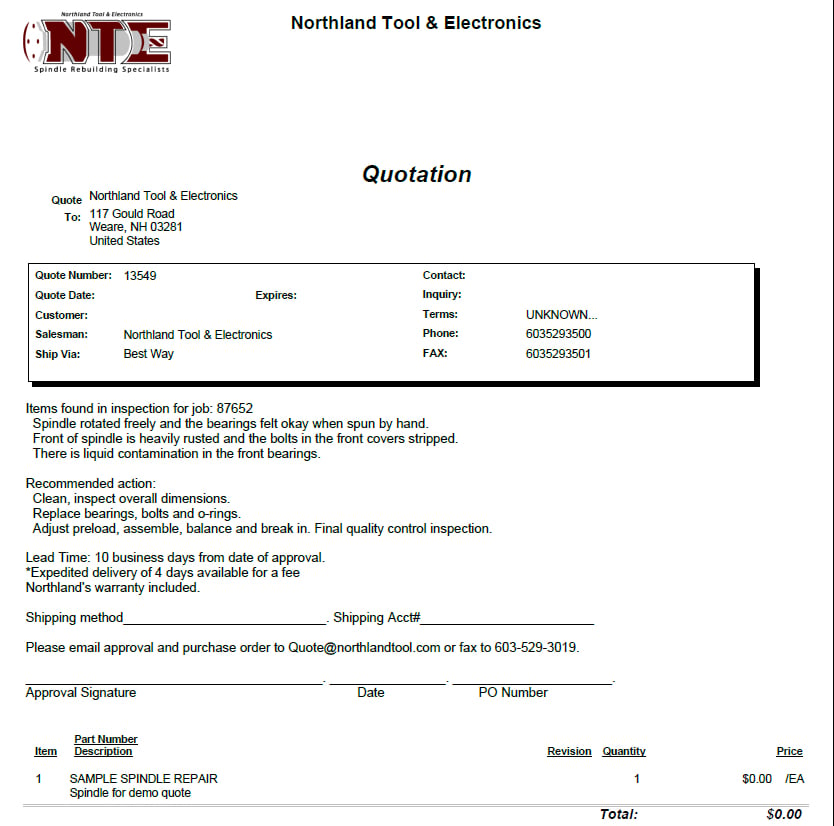

Quoting and Scheduling

-

Assembly and Delivery

- Upon arrival, we log every spindle into our production tracking software system and any issues associated with transit are noted.

- Our technicians then carefully break down the spindle into its component parts, note their general condition as well as specific damage, and perform a full dimensional inspection to identify excessive wear.

- Our production manager performs a second evaluation, during which he/she will try to identify the cause of failure, consult with the head of our grinding and machining departments, and determine any recommendations for preventative measures.

- Our purchasing department sources all replacement part costs, determines lead times, and generates a quote.

- Our team gives the quote a final check and communicates it to the customer for approval.

- Following the customer’s approval, we schedule production and order any parts needed for the repair.

- We carefully clean all parts of the spindle and complete any necessary grinding or machining operations.

- Our highly trained technicians then assemble all spindle components and perform a rigorous break-in process. This includes dynamic balancing and thermal/vibration analysis.

- After our inspectors perform a final quality control check, our shipping department carefully boxes the spindle and returns it to the customer.

1 Year Warranty

Our competitive 1 Year Warranty policy ensures that proper workmanship and parts free of defect are used in the repairing or rebuilding of every spindle. The warranty begins as soon as the repaired spindle is shipped from Northland Tool, and is valid for a period of 12 months thereafter. We will replace any parts that prove to be defective under normal use and correct any improper workmanship at no charge to the customer. Please see our full warranty terms for more details.

The Bridgeport Torq-Cut 22 is a smaller CNC vertical machining center. It comes fitted with a grease lubricated and belt driven spindle capable of running up to 7,500 rpm.

Read More

It’s a fact of machining — eventually, even top-of-the-line turning machines will experience a spindle failure. Spindles endure tension, torsion, heavy loads, and speeds up to and beyond 150,000 RPM, to name a few of the standard stressors.

Read More