The Bridgeport Torq-Cut 22 is a smaller CNC vertical machining center. It comes fitted with a grease lubricated and belt driven spindle capable of running up to 7,500 rpm.

Read More

Mazak VTC-20 Spindle Repair

The Mazak VTC-20 is a CNC vertical machining center. It comes equipped with a grease lubricated and coupling driven spindle capable of running up to 8,000 rpm.

CHALLENGE

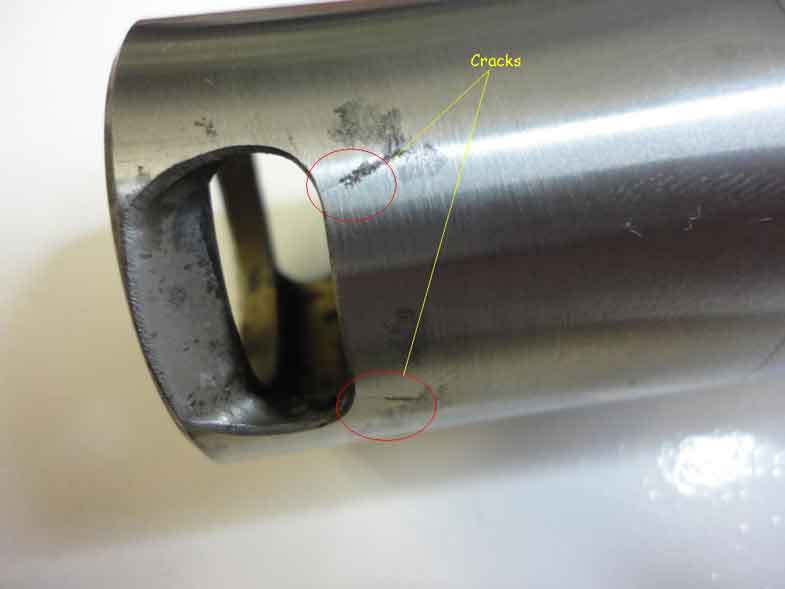

Our customer indicated that this spindle would occasionally make a banging noise while in operation. When we broke the spindle down for evaluation, we observed that the grease in the spindle bearings was partially washed out by coolant contamination. But the root cause of failure was loss of preload of the bearings, which occurred when the hydraulic nut loosened up on the rear of the shaft. The spindle-side half of the direct-drive coupling actually bolts to the hydraulic nut, so any motor misalignment or other disturbance of that connection will cause this type of failure. In this case, one of the mounting bolts had been broken off, and the coupling pilot OD and shaft mounting ID were both egged and tapered. The loss of preload also allowed the inner bearing spacer to spin on the shaft, damaging the spacer ID. We observed significant damage in the front of the spindle, including severe egging of the front bearing housing ID, severe wear, runout in the tooling taper, and a cracked gripper sleeve.

SOLUTION

Our overhaul of this vertical machining center spindle included a grind, chrome plate, and finish grind of the front bearing housing ID, the shaft CT40 tooling taper, and the inner bearing spacer ID. These grinding operations were accomplished in-house on one of our Kellenberger grinders. We also repaired the hydraulic nut and trued up the inner and outer bearing spacers in our machine shop. We replaced the bearings, belleville washers, gripper sleeve, spindle-side drive coupling, o-rings, and assembly screws.

RESULT

After reassembly of all components, adjusting bearing preload, and undergoing break-in and testing procedures, this spindle passed our final quality inspection before being returned to our customer with a 1-year warranty.

DETAILED CAUSE OF FAILURE

Does your spindle need repair? GET A QUOTE TODAY

More Case Studies

Repair History - Here are examples of similar spindle repairs that may contain additional information that will help you. If you have additional questions, please contact us.

It’s a fact of machining — eventually, even top-of-the-line turning machines will experience a spindle failure. Spindles endure tension, torsion, heavy loads, and speeds up to and beyond 150,000 RPM, to name a few of the standard stressors.

Read More