The Bridgeport Torq-Cut 22 is a smaller CNC vertical machining center. It comes fitted with a grease lubricated and belt driven spindle capable of running up to 7,500 rpm.

Read More

Kellenberger Kel-Vision URS 125 Spindle Repair

CHALLENGE

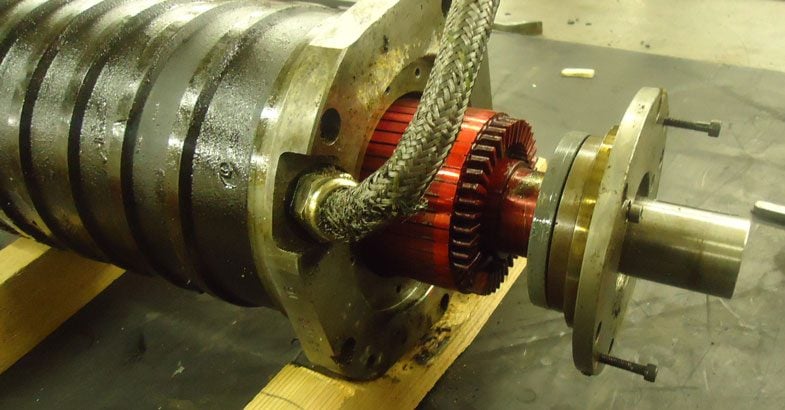

Our customer indicated that this OD grinding spindle would load up in operation and eventually lock up. When we disassembled and evaluated the spindle, we saw that the spindle shaft had rubbed out on the bronze oil bearings. It was apparent that a number of factors contributed to the failure of the hydrodynamic film between these components. The oil pump was partially seized, some oil supply fittings and fixtures were compromised, and the oil bearing main housing was missing the o-rings. Additionally, the coolant passages for the OD spindle, drive motor, and casting were plugged with grinding swarf. The OD drive motor bearings were also worn and the motor shaft shoulders had excessive runout. The ID grinding spindle was not supplied with the wheelhead, so we did not address the ID drive motor and belt tension pulley which were also seized.

SOLUTION

Our rebuild started with a grind, chrome plate, and finish grind of the OD spindle shaft journals and a kiss grind of the bronze bearings to remove the rubout damage. We also kiss ground the wheel hub taper to clean it up while the spindle shaft was up on the grinder. The shoulders of the OD motor shaft were also kissed to improve the runout, and we repaired the oil pump. After a thorough cleaning of all components, we reassembled the OD spindle & motor using new radial bearings (for the motor), drive belts, seals, o-rings, and various oil supply, vent & assembly components. We pressure tested the front & rear housings, filled the reassembled spindle with fresh oil and test ran the spindle for several hours while performing additional pressure testing. When we were satisfied that the spindle was functioning properly, we drained the spindle oil for shipping, crated it and sent it on its way.

RESULT

This spindle passed our final quality inspection before being returned to our customer with a 1-year warranty.

DETAILED CAUSE OF FAILURE

Does your spindle need repair? GET A QUOTE TODAY

More Case Studies

Repair History - Here are examples of similar spindle repairs that may contain additional information that will help you. If you have additional questions, please contact us.

It’s a fact of machining — eventually, even top-of-the-line turning machines will experience a spindle failure. Spindles endure tension, torsion, heavy loads, and speeds up to and beyond 150,000 RPM, to name a few of the standard stressors.

Read More