The Bridgeport Torq-Cut 22 is a smaller CNC vertical machining center. It comes fitted with a grease lubricated and belt driven spindle capable of running up to 7,500 rpm.

Read More

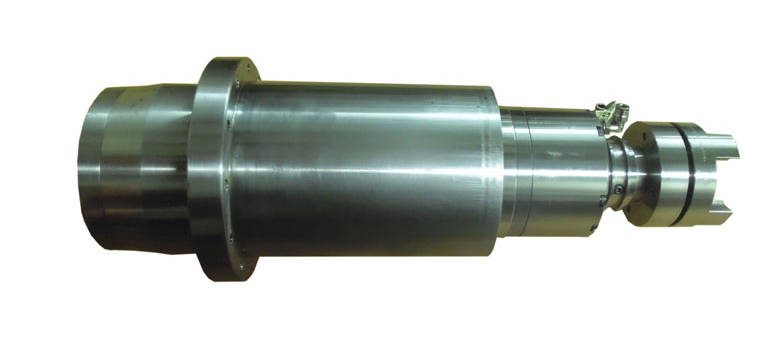

Milltronics BR5100 Spindle Repair

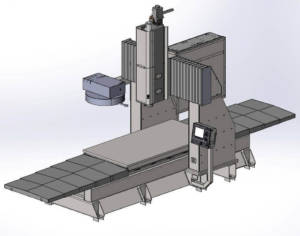

Our customer’s bridge mill spindle was not manufactured by the machine OEM, Milltronics USA Inc. The Cells D-series direct-drive spindle itself was manufactured in Taiwan by Cells Tec Co. Ltd. This is not particularly uncommon in the machine tool industry, where some OEM’s design and build their own spindles, while many others install the products manufactured by various spindle OEM’s.

This Cells D-series spindle is out of a Milltronics BR5100 CNC bridge mill. It is grease lubricated and capable of running up to 10,000 rpm.

CHALLENGE

The rebuild process itself was pretty straightforward, other than the corrosion & light damage to the tooling taper ID. The tool retention gripper fingers had been removed by the customer, who indicated that they were worn and in need of replacement. The spindle bearings were very noisy when rotated in assembly, and we did observe what seemed to be an excessive amount of bearing grease, which can lead to friction & heat buildup during operation. No other dimensional deviations were noted for this repair.

SOLUTION

The following actions were performed on this Milltronics BR5100 spindle:

- Clean all parts of the spindle

- Replace all bolts, o-rings, and bellevilles

- Replace gripper fingers and thermistor

- Replace bearings

- Kiss grind tooling taper ID

RESULT

After reassembly of all components, adjusting bearing preload, and undergoing break-in and testing procedures, this spindle passed our final quality inspection before being returned to our customer with a 1-year warranty.

Does your spindle need repair? GET A QUOTE TODAY

More Case Studies

Repair History - Here are examples of similar spindle repairs that may contain additional information that will help you. If you have additional questions, please contact us.

It’s a fact of machining — eventually, even top-of-the-line turning machines will experience a spindle failure. Spindles endure tension, torsion, heavy loads, and speeds up to and beyond 150,000 RPM, to name a few of the standard stressors.

Read More