The Bridgeport Torq-Cut 22 is a smaller CNC vertical machining center. It comes fitted with a grease lubricated and belt driven spindle capable of running up to 7,500 rpm.

Read More

Mitsubishi M-V60E Spindle Repair

The Mitsubishi MV60E is a CNC vertical machining center. It comes equipped with a grease lubricated and stator driven spindle capable of running up to 6,000 rpm.

CHALLENGE

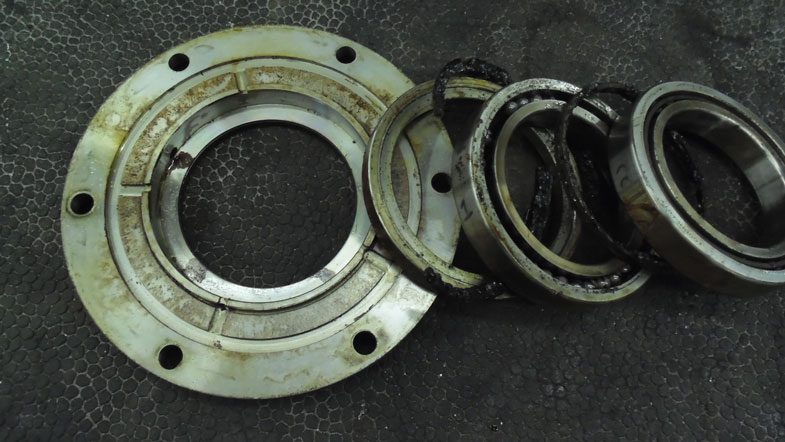

This exterior of this Mitsubishi M-V60E spindle was corroded and covered with sticky coolant residue when we received it. It was also apparent that the encoder gear located behind the rear roller bearing had several damaged teeth. Our internal inspection revealed a similar condition inside. The front of the spindle was heavily corroded and the grease had been completely washed out of the front bearing quad set. This led to failure of the #1 front bearing including the phenolic cage having broken and melted. We observed significant wear and corrosion on the gripper (collet) assembly and the rear of the drawbar, which was also bent with runout of >200µ. Our incoming measurement showed very low tool retention force which was not surprising given that the Belleville washers were compressed and most of the grease had been washed out. The tooling taper was pock marked with poor tool contact at the mouth and slightly excessive runout. This spindle had suffered greatly overall from coolant contamination though the front & back of the spindle, as well as very hard use.

SOLUTION

Despite the significant wear and damage to this spindle, the remedies were relatively uncomplicated. We put the spindle shaft up on one of our Kellenberger grinders to attend to the wear & runout in the tooling taper with a precision kiss grind. We addressed the bend in the rear of the drawbar shaft by straightening it in our machine shop. We then reassembled the spindle with all new bearings, bellevilles, grippers, encoder gear, o-rings, and assembly screws.

RESULT

After reassembly of all components, adjusting bearing preload, and undergoing break-in and testing procedures, this spindle passed our final quality inspection before being returned to our customer with a 1-year warranty.

DETAILED CAUSE OF FAILURE

Does your spindle need repair? GET A QUOTE TODAY

More Case Studies

Repair History - Here are examples of similar spindle repairs that may contain additional information that will help you. If you have additional questions, please contact us.

It’s a fact of machining — eventually, even top-of-the-line turning machines will experience a spindle failure. Spindles endure tension, torsion, heavy loads, and speeds up to and beyond 150,000 RPM, to name a few of the standard stressors.

Read More