The Bridgeport Torq-Cut 22 is a smaller CNC vertical machining center. It comes fitted with a grease lubricated and belt driven spindle capable of running up to 7,500 rpm.

Read More

Mori Seiki NZ2000 Spindle Repair

The Mori Seiki NZ2000 is a CNC turning center. The spindle we repair is the main spindle for turning. It is grease lubricated, stator driven, and capable of running up to 4,000 rpm.

CHALLENGE

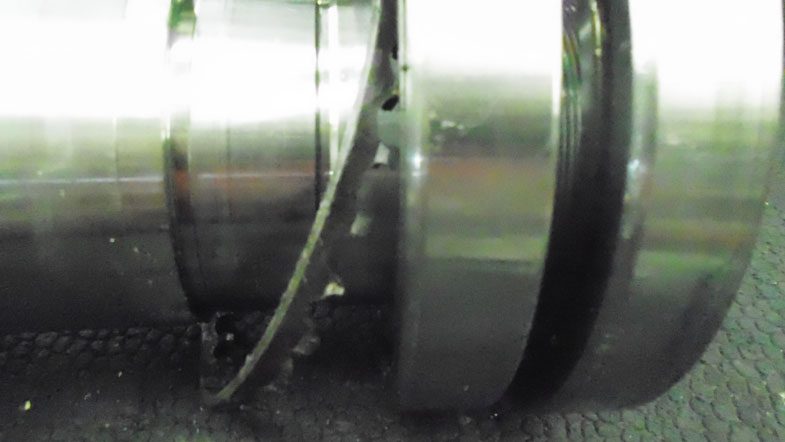

Our inspection of the front quad set of angular contact bearings in this modern turning spindle showed that the #3 bearing had suffered catastrophic failure. When the cage disintegrated, the debris contaminated the adjacent #2 bearing. We did not find evidence of excessive heat, coolant contamination or bearing misalignment, so we could only assume that the #3 bearing had simply reached the end of its useful life. Our dimensional evaluation did find that the rear housing bore was egged 10µ, but fortunately this had not adversely affected the rear roller bearing.

SOLUTION

We recommended green grinding, hard chromium plating, and finish grinding the rear housing bore to forestall possible premature failure of the rear roller bearing. We also recommended substituting angular contact bearings with large steel rolling elements, rather than using bearings with small steel balls as found in the spindle. We felt that this modification would provide more appropriate axial and radial rigidity for our customer’s application while reducing their cost and still maintaining an appropriate speed rating.

RESULT

After reassembly of all components, adjusting bearing preload, and undergoing break-in and testing procedures, this spindle passed our final quality inspection before being returned to our customer with a 1-year warranty.

DETAILED CAUSE OF FAILURE

Does your spindle need repair? GET A QUOTE TODAY

More Case Studies

Repair History - Here are examples of similar spindle repairs that may contain additional information that will help you. If you have additional questions, please contact us.

It’s a fact of machining — eventually, even top-of-the-line turning machines will experience a spindle failure. Spindles endure tension, torsion, heavy loads, and speeds up to and beyond 150,000 RPM, to name a few of the standard stressors.

Read More