The Bridgeport Torq-Cut 22 is a smaller CNC vertical machining center. It comes fitted with a grease lubricated and belt driven spindle capable of running up to 7,500 rpm.

Read More

Mori Seiki SH-400 Spindle Repair

The Mori Seiki SH-400 is a CNC horizontal machining center. It comes equipped with an oil mist lubricated and stator driven spindle capable of running up to 12,000 rpm.

CHALLENGE

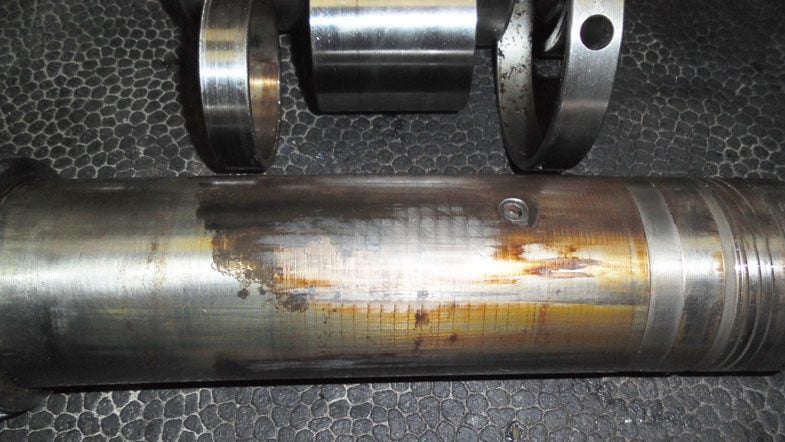

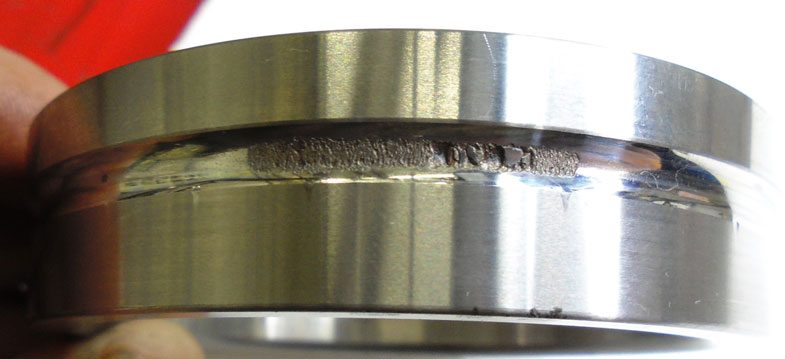

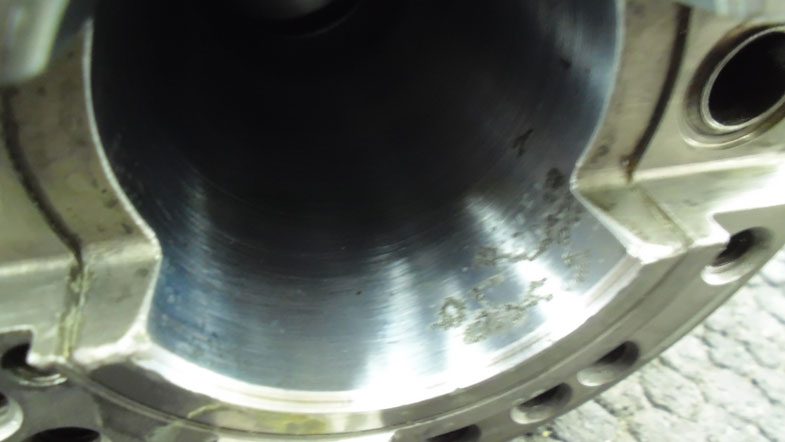

Our customer was experiencing poor part finish and assumed correctly that the bearings had lost preload. They initially did not provide the drawbar assembly, front splash ring, nor the coolant assemblies. During our pre-quote evaluation we determined that the front quad set of bearings had failed from coolant contamination. The spindle was full of a sticky coolant residue and the inner races of the #1 and #2 bearings had spalling damage. The inner bearing spacer was corroded onto the spindle shaft but fortunately the bearing journals were not adversely affected. We observed pitting of the tooling taper ID with excessive runout of >6µ. We also noticed that the rear roller journal had been previously plated and ground slightly oversized, but not to a significant degree.

SOLUTION

We corrected the runout in the tooling taper by kiss grinding it on one of our Kellenberger universal grinding machines. We rebuilt the spindle with new bearings, o-rings, oil lines, ferrules, and assembly screws. We did not replace the coolant assemblies as the customer opted to replace them when the spindle was reinstalled. At our request, the customer supplied the drawbar assembly so we could balance the entire spindle. In this particular case, the customer asked us not to service the drawbar assembly as they felt it required no attention.

RESULT

After reassembly of all components, adjusting bearing preload, and undergoing break-in and testing procedures, this spindle passed our final quality inspection before being returned to our customer with a 1-year warranty.

DETAILED CAUSE OF FAILURE

Does your spindle need repair? GET A QUOTE TODAY

More Case Studies

Repair History - Here are examples of similar spindle repairs that may contain additional information that will help you. If you have additional questions, please contact us.

It’s a fact of machining — eventually, even top-of-the-line turning machines will experience a spindle failure. Spindles endure tension, torsion, heavy loads, and speeds up to and beyond 150,000 RPM, to name a few of the standard stressors.

Read More