Spindle Vibration Monitoring & Analysis

What Is Vibration Analysis?

In manufacturing, vibration analysis is a process for measuring the vibration levels and frequencies of machinery and its components while in operation. The analysis is performed both during machine repair troubleshooting and as a part of preventive maintenance.

Vibration analysis determines whether there are defect frequencies that need to be addressed. Too much vibration in equipment can cause:

- Damage to equipment

- Parts failure

- Production of substandard parts

- Expensive downtime

- Possible injury due to malfunction

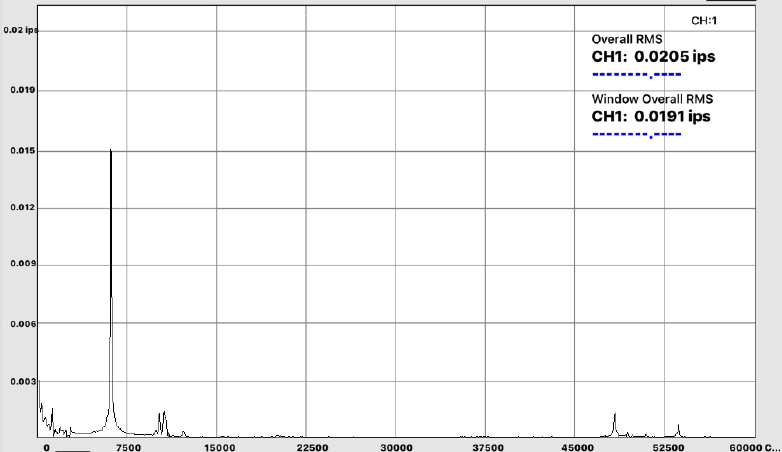

When machinery is in operation, it emits vibration signals at several frequencies with different levels of amplitude. These signals are measured with an accelerometer containing a piezoelectric crystal component — such as quartz — which generates an electric charge. This output is delivered to a vibration analyzer that provides a visual representation of the vibration spectrum in graph form. Using this graph, the technician can determine if there is a defect frequency as well as the severity of the defect.

The information in this readout can then be trended over time for predictive maintenance scheduling or instant troubleshooting processes.

What Is Spindle Vibration Analysis?

In spindle vibration analysis, vibration testing equipment is used to diagnose or assess the health of a spindle. At Northland Tool, we conduct vibration testing and analysis on every spindle we repair.

When a spindle arrives in our facility, we use vibration testing to assess overall spindle health and detect any problems, including those not identified by the customer.

After the assembly of the spindle, vibration analysis enables us to be certain that we are returning a healthy spindle that adheres to Northland’s very high standards.

Causes of Spindle Vibration

Spindle vibration is caused by a number of factors:

- Bearing defects

- Bearing journal / housing bore out of tolerance

- Incorrect bearing lubrication

- Incorrect spindle mounting

- Misaligned spindle components

- Out-of-balance assembly and interactions between rotating parts

- Out-of-tolerance tooling interfaces

- Resonant frequencies

- Low spindle bearing preload

- Spindle crashes

Why Is Spindle Vibration Analysis Important?

If left unchecked or unaddressed, spindle vibration that is outside of acceptable specifications can lead to poor part finish, defective parts, or premature spindle failure — all of which can result in expensive downtime for repairs.

The foundation of any good predictive maintenance program is thorough vibration monitoring and analysis. By measuring the overall vibration of a spindle, technicians can identify and diagnose any number of issues, including:

- Bearing failures

- Bent shafts

- Critical speeds

- Motor faults

- Gearbox failures

- Imbalance

- Mechanical looseness

- Misalignment

- Resonance and natural frequencies

Spindle Vibration Analysis Tools & Software

Vibration measurements are usually taken while the spindle is in operation. Using a portable analyzer and vibration analysis software, an accelerometer translates frequencies via electric charge into a visual, readable format. This software can measure for different metrics, such as speed and temperature, and will alert the technician to any vibration or other metric that has exceeded the acceptable specification.

Stored within this software is the vibration history for any given machine, which technicians can save and print for planning and review purposes.

At Northland Tool, our spindle repair technicians use a variety of vibration analysis tools and software.

Can I Do a Spindle Vibration Analysis Myself?

Vibration readings can be performed easily by just about anyone with the proper tools and software. Where experience is needed is in determining what the readings mean.

There are many third parties that can perform onsite vibration analysis. They typically charge per hour plus travel expenses; there is also a fee for compiling the information and providing a summary of their findings.

If you have any questions regarding spindle vibration analysis, give us a call today. With more than 40 years of experience, our spindle repair technicians will provide you with expert analysis and guidance.

- Machine Tool Spindle Bearing Lubrication: What To Know

- Delaying Spindle Service Causes More Damage, Costly Repairs

- What Does It Mean to Be a Factory Authorized Big Plus Spindle Rebuilder?

- Precision Machining in a World of Microns

- GPG: Grind-Plate-Grind Process Explained

- What Is the Spindle Repair Process?