What Is the Spindle Repair Process?

The anatomy and functionality of a spindle is complex. And as such, it takes true expertise to understand, troubleshoot, and repair spindles correctly.

The anatomy and functionality of a spindle is complex. And as such, it takes true expertise to understand, troubleshoot, and repair spindles correctly.

Simply put, a spindle repair company should have the experience and expertise to repair your spindle the right way.

After a spindle repair is complete, one of the best tools a repair shop can provide its customers with is a ‘spindle support program.

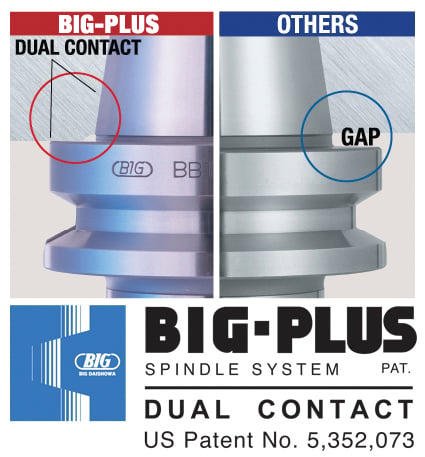

The ability to rebuild a BIG PLUS spindle is a specialty few spindle repair companies possess.

Northland Tool & Electronics was recently invited to the Hardinge Machine Technology Show 2014 in Elmira, NY where we exhibited as a Technology Partner.

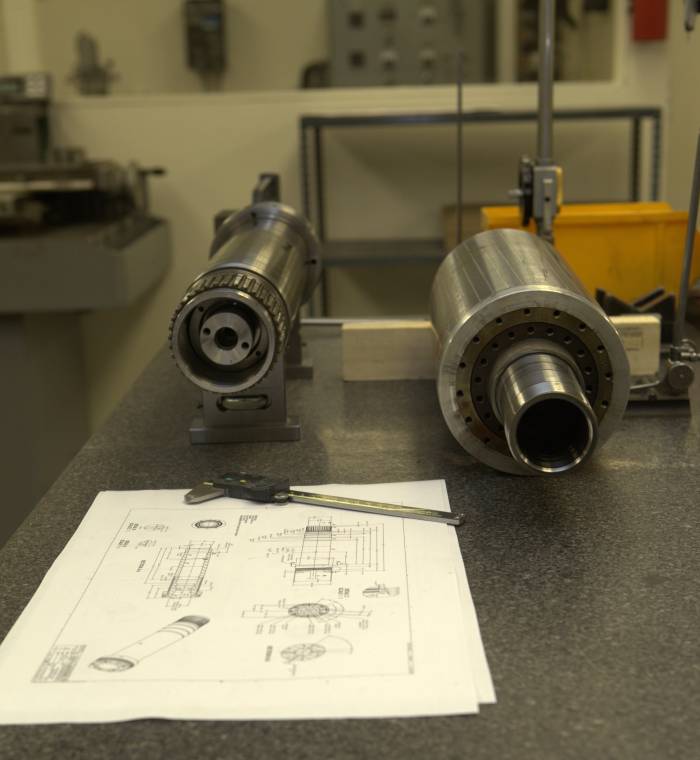

Our customer, a large tooling manufacturer, was experiencing a loud, roaring noise and poor part finish with this double-ended grinding spindle.

Possible cause of failure: Catastrophic failure of #1 and #2 front bearings. Shaft 40 taper is below gauge line. OD of shaft nose has a large dent, drive dogs have light cosmetic wear.

Possible cause of failure: Bearings noisy from use and contamination. 50 taper worn with low spots. Drawbar force is low. Drive dogs have wear marks. Grippers worn from use.

Possible cause of failure: Bearing failure from contamination in the front and rear. Rear of spindle covered with dried coolant.

Possible cause of failure: All bearings are contaminated. Front and rear shaft journals, shoulder and pilot are not at ISO. Rear pulley taper area and face are marked up.