Mitsui Spindle Rebuild

This spindle had been recently rebuilt by someone else before it arrived at NTE. It was running very hot and seizing in our customers machine. The heat was caused by too much grease in the bearings.

This spindle had been recently rebuilt by someone else before it arrived at NTE. It was running very hot and seizing in our customers machine. The heat was caused by too much grease in the bearings.

Possible cause of failure: Shaft nose has heavy rub out damage from being crashed. Id shaft collet taper has 10-12 microns runout. Od is very rough Timing pulley teeth are very worn.

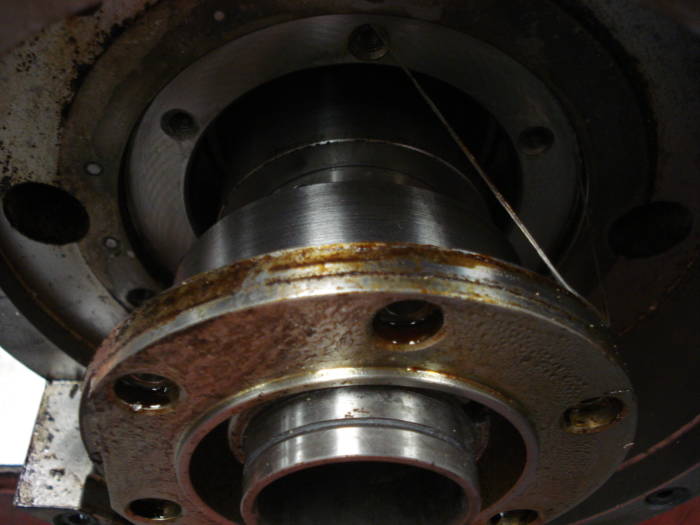

Possible cause of failure: Spindle arrived seized, missing the drawbar assembly. Spindle bearings failed from coolant contamination, grease was washed out and full of rust.

The rotor of this spindle had broken loose from the shaft causing end play or axial movement of the shaft.

Possible cause of failure: Front bearing is worn Taper has 12 microns runout Spindle has been crashed Repair action: Clean, inspect overall dimensions Replace bearings Kiss grind taper Adjust preload,…

Possible cause of failure: Spindle was crashed Pilot has 8 microns runout Ball cage is loose with varying ball sizes Repair action: Clean, inspect overall dimensions Replace bearings and balls Grind c…

Summer Can Mean Stress for Your Spindle Summer is almost here and Northland Tool & Electronics would like to bring a few things to your attention that can help extend the life of your spindles dur…

There are many benefits of a ceramic conversion program by Northland Tool & Electronics, including: Service: Our staff will be in contact with you all the way through the spindle repair process, a…

Our customer acquired several Okuma Howa machines from a sister plant that closed. The installation of the machines was anything but smooth.

Bryant WBA Grinding Spindle 70,000 rpm Thru Tool Coolant An automotive company in the mid-west contacted me regarding their Bryant grinding spindles.