The Bridgeport Torq-Cut 22 is a smaller CNC vertical machining center. It comes fitted with a grease lubricated and belt driven spindle capable of running up to 7,500 rpm.

Read More

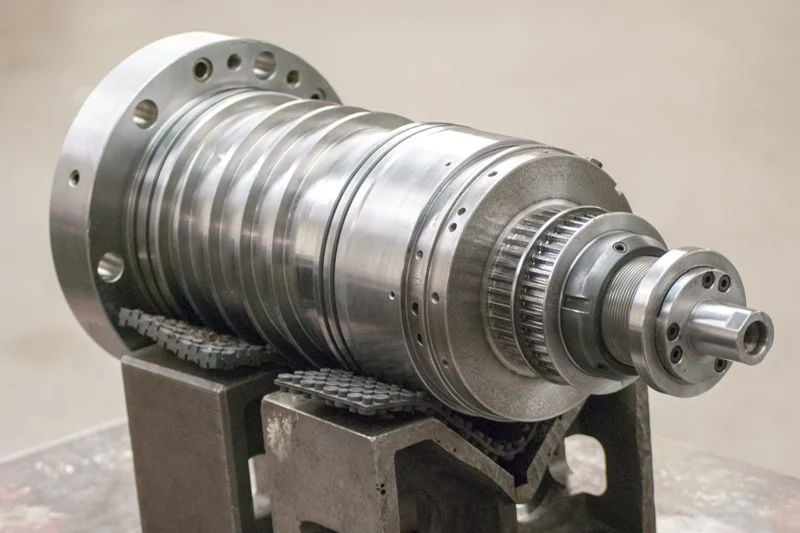

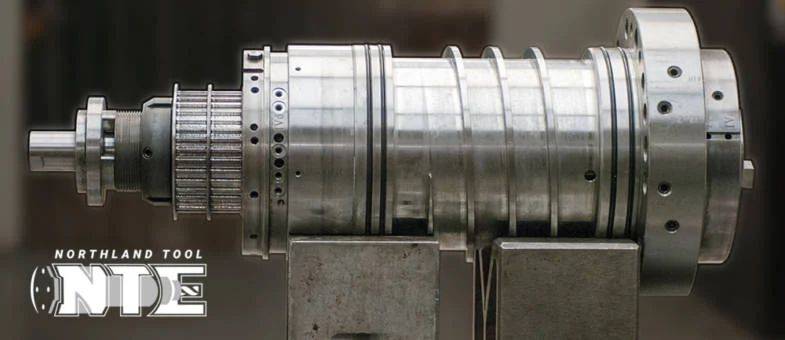

Weiss 176191-476 Spindle Repair

CHALLENGE

Our customer had a Weiss 176191 spindle failure in a Bridgeport XR1000 VMC. Upon initial inspection, we found that the tooling taper ID had visible damage, with severe bell-mouthing as well as surface damage further up the taper. Disassembly of the spindle revealed that the #1 front bearing had suffered catastrophic failure with a disintegrated cage, which resulted in contamination of the rest of the quad set. Grease in all bearings was completely washed out, and there was evidence that the rear roller bearing had been flooded with coolant. The 70mm front journal on the shaft measured with 6µm runout where the #1 bearing was positioned. Gripper fingers (collet) showed significant wear on critical tool retention surfaces.

SOLUTION

Weiss manufactures this particular spindle with a grease injection system, which requires periodic maintenance and significantly increases the cost of ownership over time. This type of grease injection system requires that operators maintain two expensive grease cartridges. We have developed a reliable method to plug the injection ports and convert Weiss spindles to use permanent grease, which saves time and money for our customers.

Every incoming spindle to Northland Tool is inspected to measure all critical dimensions, then thoroughly cleaned. This repair required a grind, chrome-plate, finish grind to the tooling taper ID and the 70mm front journal. We replaced all bearings, Bellevilles, grippers, seals, o-rings and assembly screws. The spindle entered the final phase of the repair process when we adjusted preload, assembled, balanced, and break-in before testing and final quality control inspection.

RESULT

Every Northland Tool repair is covered by a comprehensive 1-year warranty.

DETAILED CAUSE OF FAILURE

Does your spindle need repair? GET A QUOTE TODAY

More Case Studies

Repair History - Here are examples of similar spindle repairs that may contain additional information that will help you. If you have additional questions, please contact us.

It’s a fact of machining — eventually, even top-of-the-line turning machines will experience a spindle failure. Spindles endure tension, torsion, heavy loads, and speeds up to and beyond 150,000 RPM, to name a few of the standard stressors.

Read More