Gamfior Spindle Repair Programs

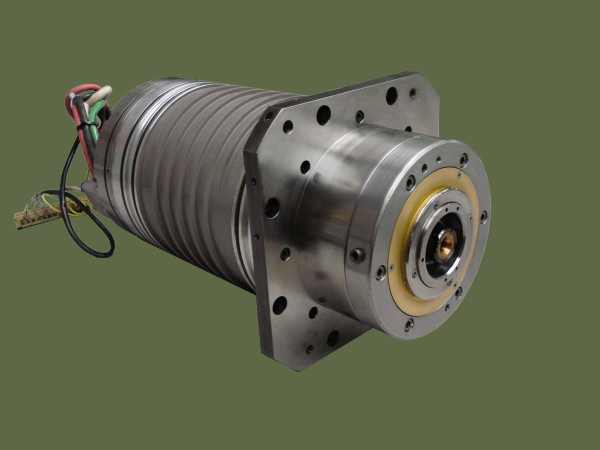

Gamfior E13779M

One of our success stories in the aerospace industry comes from a manufacturer of wing spars. Their 5 axis machines were experiencing frequent spindle failures and it was taking the OEM in excess of 30 days to complete the repairs. This lead to them purchasing 2 spare spindles for each machine they were running. The first thing we did when we were called in was to perform an on-site evaluation. We met with the plant manager and the maintenance department to determine the scope of the problem and the goals for the spindle repair program. We then evaluated each machine individually looking at all the spindle related components, lubricators, chillers, tool change mechanisms, electrical systems and performed vibration analysis to each spindle. Once we established a baseline we worked closely with our customer giving them possible causes for the spindle failures they experienced and providing them with solutions. Our customer also shared pertinent information with us such as spindle crashes and machine issues that may have affected the spindle performance.

Six months after implementing our spindle repair program their spindle expenditures decreased by a factor of three. At the current time they have not required a spindle repair on the machines we have in the program for over a year and a half. When we started with them they averaged a spindle repair every three months, per machine!!!

Contact us for more information

- Machine Tool Spindle Bearing Lubrication: What To Know

- Delaying Spindle Service Causes More Damage, Costly Repairs

- What Does It Mean to Be a Factory Authorized Big Plus Spindle Rebuilder?

- Precision Machining in a World of Microns

- GPG: Grind-Plate-Grind Process Explained

- What Is the Spindle Repair Process?