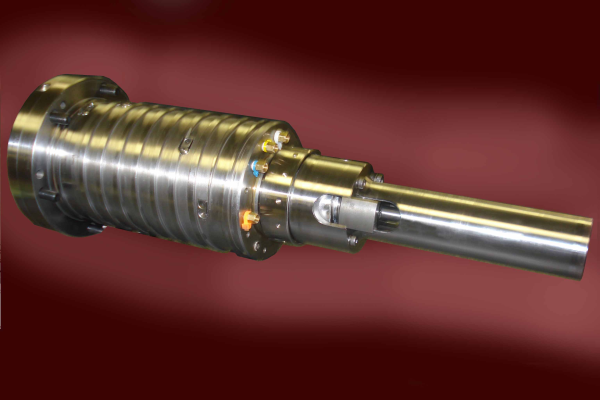

Mazak VTC200B Spindle Repair

Mazak VTC200B

12,000 rpm

40 taper

Oil Mist Lubrication

This customer has multiple Mazak VTC200B machines in their facility that were experiencing frequent spindle failures. We disassembled the first spindle and found that the design was very poor. The nut for the rear bearings was hydraulic and had the long shaft that attaches to the drive motor bolted to it. The problem with this setup occurs if there is any misalignment with the drive motor, any vibration in the drive motor or if any number of ground surfaces are not virtually perfect. Any flaws in these areas subjects stress directly to the rear bearing causing premature failure. To compound these issues the drawbar system that requires significant forces to function is included in this assembly. We discussed these findings with our customer and mutually decided the best course of action was to replace the shaft, hydraulic nut and drive motor tube. This was the only way to insure proper fits and run outs. Special care will also need to be taken during the installation process to insure proper alignment and balance.

- Machine Tool Spindle Bearing Lubrication: What To Know

- Delaying Spindle Service Causes More Damage, Costly Repairs

- What Does It Mean to Be a Factory Authorized Big Plus Spindle Rebuilder?

- Precision Machining in a World of Microns

- GPG: Grind-Plate-Grind Process Explained

- What Is the Spindle Repair Process?