Spindle Basics

How to Recognize Bad Spindle Symptoms

It’s a fact of machining — eventually, even top-of-the-line turning machines will experience a spindle failure. Spindles endure tension, torsion, heavy loads, and speeds up to and beyond 150,000 RPM, to name a few of the standard stressors. Some amount of wear and maintenance is expected — but if a tell-tale sign of a bad spindle goes unnoticed for too long, a failure is probably imminent. While you can’t predict the unpredictable, you can take preventative measures to ensure your spindle has the longest life possible.

Read More

Housing, Shaft, and Bearing Fits for Precision Spindles

The success of any precision machinery relies heavily on various intricate components working seamlessly in unison. Among these components, machine spindle shaft, housing, and bearing fits play a crucial role in ensuring optimal output and system longevity. Here, we discuss the significance of different types of bearing, shaft, and housing fits and how they affect the performance of precision spindles.

Read More

Minimizing Spindle Downtime: Preventative Maintenance & More

Downtime is inevitable for any machine, but knowing how to reduce downtime or minimize its likelihood is critical. Since the spindle component of any machine experiences the most wear, any maintenance plan must address spindle health and downtime prevention. Preventative spindle maintenance and monitoring can increase productivity and profits, improve parts quality, reduce repair costs, and ensure operators’ safety.

Read More

Spindle Noise: Potential Causes & Troubleshooting

One of the most valuable tools for identifying spindle issues is sound. Spindle assemblies vibrate naturally during operation, but excessive vibration that causes unusual noise is a sign that something could be wrong.

Read More

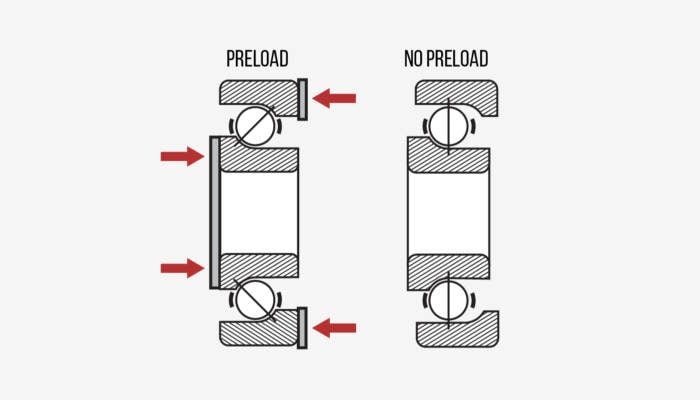

What Is Spindle Bearing Preload and Why Is It Done?

In this helpful guide to spindle bearing preload, Northland Tool & Electronics will answer all the basic questions about your spindle bearing preload calculations. More importantly, we’ll discuss exactly why this is so crucial to the performance and longevity of your spindle. What Is Spindle Bearing Preload? First, let’s define preload. Preload is a predetermined static load that applies to all rolling components evenly. Specifically, bearing preload keeps the rolling elements in constant contact with the races to ensure that the dynamic loads, while in use, are exactly where they need to be to maximize accuracy and spindle life span.

Read More

Radial & Axial Runout Explained

In machining, runout refers to inaccuracies in a tool or piece of equipment that cause it to spin off its ideal axis. Spindle runout occurs when a spindle no longer rotates on its intended axis, which can result in: Inaccurate machine registration Issues with tolerance control Excessive chip load Poor part finishes Insufficient tool life Because of these risks, it’s recommended that you test your spindles for runout regularly and obtain necessary repairs as soon as possible. There are two types of spindle runout: radial and axial. Both can lead to similar issues.

Read More