Featured Repairs

Matsuura MAM72-25V Spindle Repair

The Matsuura MAM72-25V is a CNC vertical machining center designed for 5-axis machining. The main spindle is grease lubricated and coupling driven capable of running up to 15,000 rpm.

Read More

Weiss 176162 Spindle Repair

When our customer first contacted us about this Weiss 176162 spindle, they were limiting the spindle speed to 4-5000 RPM (capable of 15,000 rpm) because it was emitting a loud, high-pitched squeal if run any faster. A week later, they were unable to go past 1000 RPM without it screaming, and the tools were coming out hot. This busy aerospace manufacturer needed to complete an order for a customer so they proceeded to run the spindle for another several months in their Hardinge Bridgeport XR500 5AX (5-axis vertical machining center).

Read More

Ingersoll T1000 Spindle Repair

Northland Tool & Electronics has worked closely with our customer, a large automobile manufacturer, for over 20 years maintaining the spindles in their Ingersoll machines. Our customer incorporates a progressive predictive maintenance program in their facility and Northland Tool is encouraged to provide input on spindle failures and corrective actions. Our customer contacted Ingersoll and Northland Tool to review this information and determined it would…

Read More

Hardinge Spindle Repair

A returning customer called us about this Hardinge 10,000 rpm spindle. After two years of running the spindle, it started to make a high pitched noise. The customer’s machine tool repairman went in and told them it was belt noise. The customer adjusted belts and the spindle was quiet again. A month later, they called in and the spindle was no longer running and the spindle was coming in for evaluation.

Read More

Walter DB112005 Spindle Repair

The Walter DB112005 is a dual OD taper grinding spindle. It comes equipped with a grease lubricated and belt driven spindle capable of running up to 10,000 rpm.

Read More

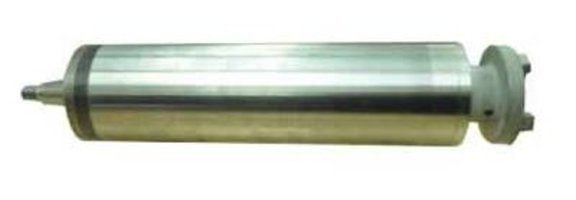

Niigata SPN40 Spindle Repair

The Niigata SPN40 is a CNC horizontal machining center. It comes equipped with an oil mist lubricated and coupling driven spindle capable of running up to 12,000 rpm.

Read More

Fanuc Robodrill Spindle Repair

This Fanuc Robodrill spindle is grease lubricated and belt driven. This makes it capable of running up to 8,000 rpm.

Read More

Topper Spindle Repair

This Topper spindle is grease lubricated, belt driven, and capable of running up to 8,000 rpm.

Read More

Mitsui Grinding Spindle Repair

This spindle had been recently rebuilt by someone else before it arrived at NTE. It was running very hot and seizing in our customers machine. The heat was caused by too much grease in the bearings. This condition makes the balls of the bearings “plow” through the grease causing resistance and heat. This heat causes the bearings to expand and eventually the clearance between the…

Read More

Fortuna FIV60R250.44 Spindle Repair

The Fortuna FIV60R250.44 is an ID grinding spindle. The spindle we repaired here is grease lubricated, belt driven, and is capable of running up to 24,000 rpm.

Read More