News & Events

Ceramic Bearings vs. Steel Bearings: Your Complete Guide

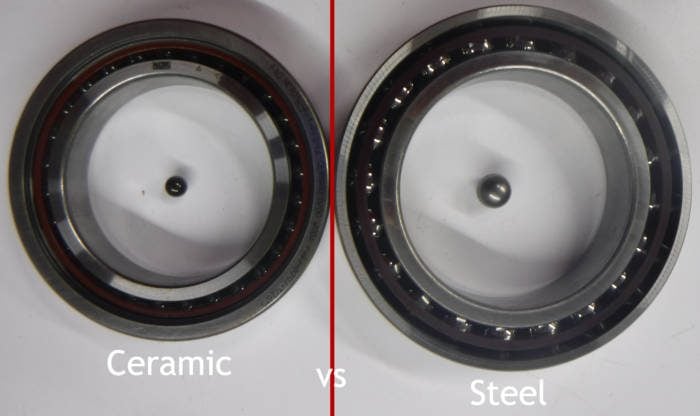

The Importance of Bearings Inside each spindle is a set of ball bearings that must hold very tight tolerances, withstand extreme conditions, and also last for many years. To accomplish all this, there are different types of bearings manufactured for very specific applications. Two variations of ball bearings that inspire a lot of questions are ceramic vs. stainless steel. At Northland Tool & Electronics, we get asked quite often if we can “upgrade” steel bearings to ceramic. Ceramic and steel ball bearings are very similar in design.

Read More

Spindle Parts & Accessories

Replacement parts are often necessary when repairing or rebuilding spindles. At Northland Tool & Electronics, all parts and accessories we order for our customers come from leading industry manufacturers. We can also service parts and accessories related to spindle motors and live tooling. Our team has substantial experience in assessing and addressing spindle part failures in a timely manner. Spindle Parts Repair Capabilities Our team of highly skilled technicians has the ability to repair, rebuild, and acquire necessary parts for hundreds of spindle brands and models on the market.

Read More

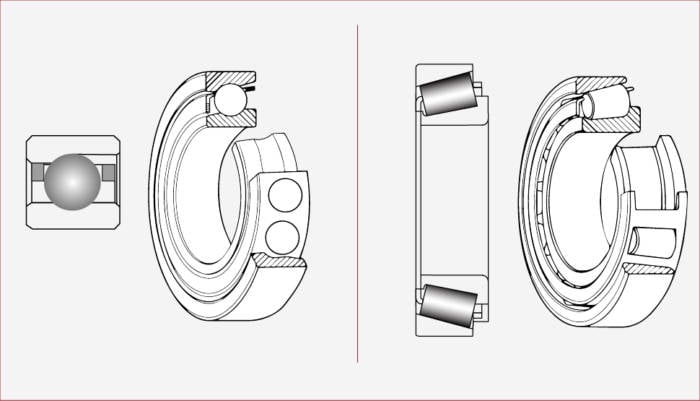

Spindle Bearing Types: Roller, Angular, Radial & More

Spindles are the heart of each and every machine tool, from the aerospace industry to automotive and medical equipment manufacturing. They can come in a variety of different sizes and are capable of many different applications. Inside each spindle is a set of bearings that must hold very tight tolerances, withstand extreme conditions, and last for many years. As such, there are different types of bearings manufactured for very specific applications.

Read More

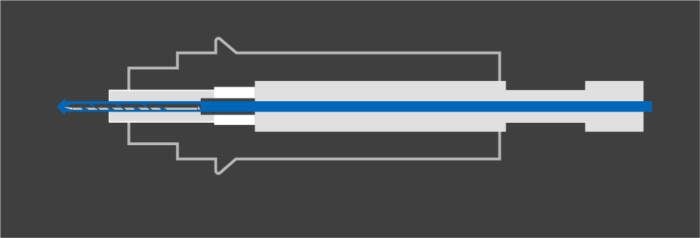

Through-Spindle Coolant: Pros, Cons & How It Works

What is Through-Spindle Coolant? By forcing coolant through the tip of the rotary tool, through-spindle coolant (TSC) can prevent damage to workpieces, reduce cycle time, and extend the life of your tool. Depending on the application, coolant can be water-based, petroleum-based, or an emulsion of oil and water. Though most machine tool manufacturers offer TSC as an option, many machines are equipped with a flood coolant system by default. In a flood coolant system, coolant is sprayed onto a tool and workpiece externally.

Read More

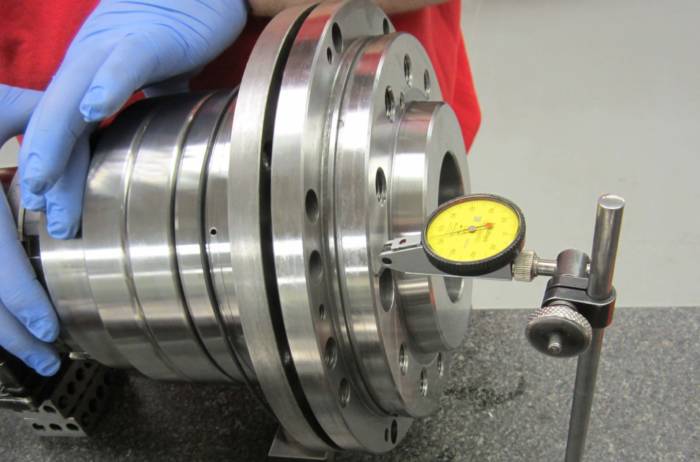

The Complete Guide to Spindle Runout: How to Test, Measure & Reduce

What Is Spindle Runout? Types of Spindle Runout The Effects of Spindle Runout How To Measure Spindle Runout Correct Your Spindle Runout Today What Is Spindle Runout? In machining, runout refers to inaccuracies in a tool or piece of equipment that cause it to spin off its ideal axis.

Read More

Delaying Spindle Service Causes More Damage, Costly Repairs

Running this spindle too long caused deformed ball bearings and damage to the outer race Damage to the outer race is consistent with prolonged operation after spindle exhibited initial signs of needing to be rebuilt Every spindle rebuilt by Northland Tool is backed by a 1-year warranty on parts and workmanship Over 2 years in the making A customer reached out to us over 2 years ago with a complaint that their spindle was starting to get noisy. We provided an estimated cost of $5,000 to rebuild.

Read More

GPG: Grind-Plate-Grind Process Explained

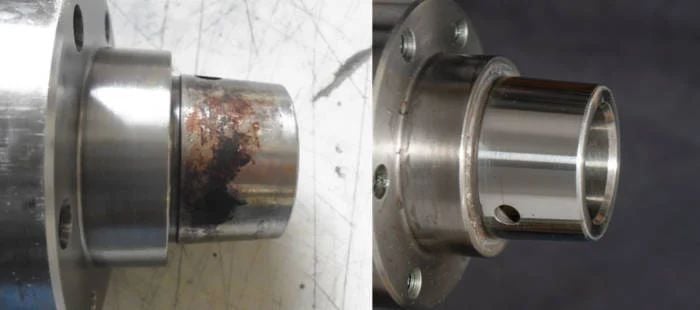

When a cylindrical surface, such as the OD of a shaft or the ID of a tooling taper, becomes worn or damaged, we use a process referred to as grind-plate-grind (GPG) to restore dimensions to original OEM specification. First, we pre-grind, also referred to as “green grind,” to remove a thin layer of material and smooth any damage. Next, the part undergoes an electroplating process to apply a layer of hard chrome to the desired area. This builds up a durable surface that is slightly oversized than the final desired dimension.

Read More

Southtec 2017

We are having a great show at Southtec 2017. Not only have we been able to introduce our unique spindle repair service, we have Kent Queensbury from Lion Precision demonstrating The Spindle Check system. If you have not seen this amazing technology yet contact us and we will be happy to give you a demonstration. This is a must have tool in your arsenal.

Read More